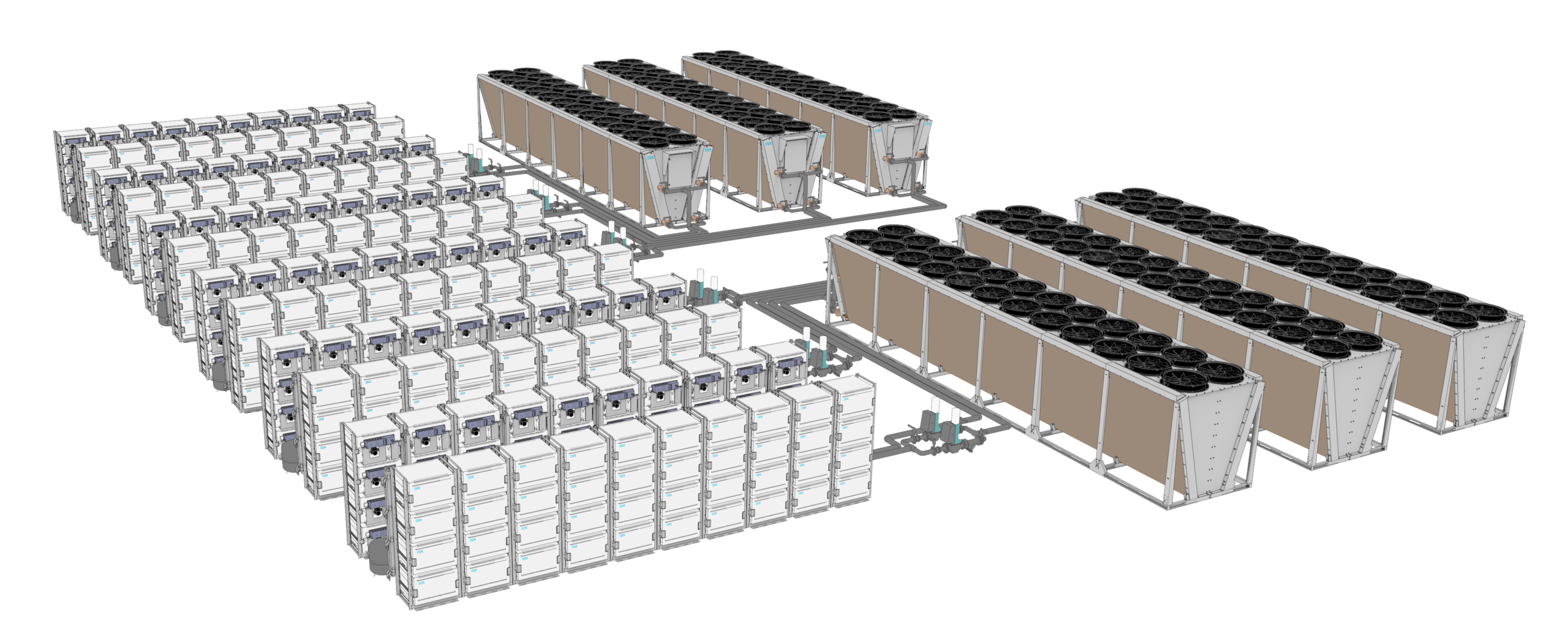

Scale-out solutions for industrial mining: containers and facility systems.

Reliable and affordable liquid cooling solution providing energy savings.

Unparalleled hashrate increase and full protection.

Press Announcement: DCX Records 215% Revenue Increase In 2022.

Press Announcement: DCX Records 215% Revenue Increase In 2022.

Press Announcement: DCX Records 215% Revenue Increase In 2022.

Press Announcement: Launch Of DCX Hydro Direct Liquid Cooling Systems.

Press Announcement: Launch Of DCX Hydro Direct Liquid Cooling Systems.

Press Announcement: Launch Of DCX Hydro Direct Liquid Cooling Systems.

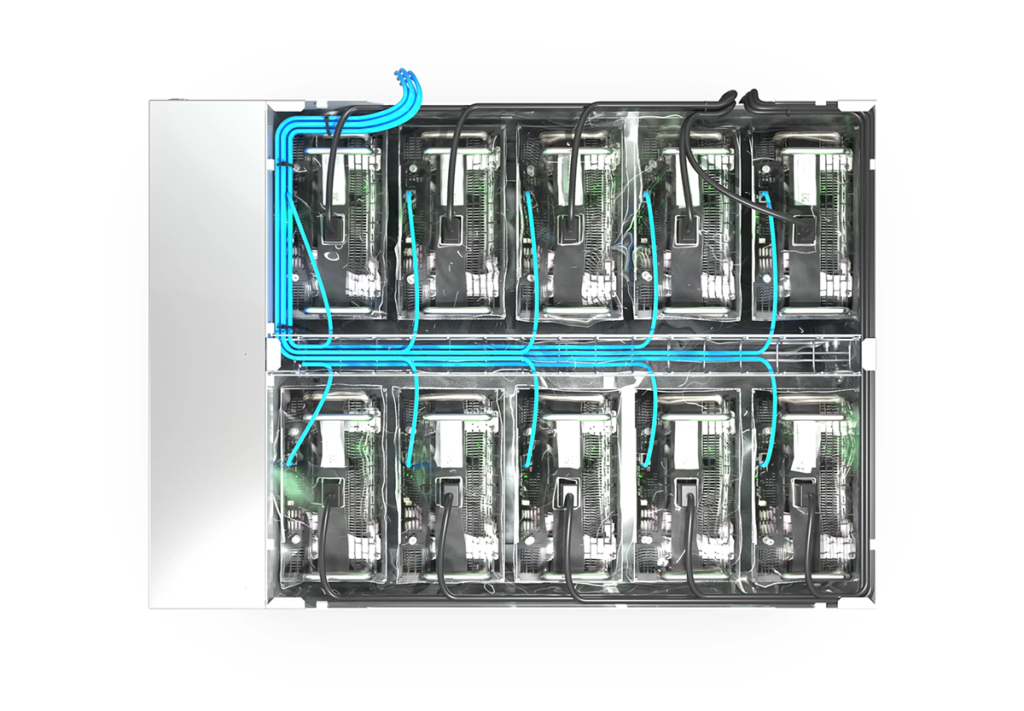

DCX PRO 10 IMMERSION

COOLING SYSTEM

The most powerful and dense crypto mining immersion system in the world

OVERVIEW

Two years ago, DCX pioneered introducing scalable and modular Immersion Enclosure & Immersion Rack System. Now being a global leader in liquid cooling solutions for the crypto mining industry, we offer a new generation of immersion systems – the PRO10 product line encompassing 3 platforms: PRO10 Immersion Mining Enclosure, PRO10 Immersion Mining Rack and PRO10 High Density Immersion Mining Container. We engineered this system from ground up to deliver heat transfer capacity, required by new miner types, including immersion miners as MicroBT M56 Whatsminer or significantly overclocked Bitmain Antminers. This performance positions DCX at the forefront of the rapidly expanding market.

DCX PRO10 Enclosure:

The most effective immersion cooling tank in the world. Dedicated for new high-powered overclocked ASIC configurations, merging state-of-the art engineering, integrated sensors with TFT screen, remote temperature monitoring & reporting service, with up to 64 kW heat transfer from single enclosure. PRO10 Immersion Mining Enclosure host up to 10 MicroBT M56 Whatsminers, 12 M30/M50 Whatsminers or 8 x Bitmain s19 Antminers. DCX Enclosure has been designed for heat reuse applications – elevated temperature set point enables sustainable and effective heat utilization. Efficient cooling allows crypto mining operation in the hottest areas of the globe, including the Middle East.

DCX PRO10 Rack System

Based on PRO10 Immersion Enclosures delivers up to 256 kW heat transfer from single Rack. PRO10 Immersion Mining Racks can be configured in rack groups in multi-MW installations, installed in facility or container system, delivering unmatched density and savings for a scale out mining operation. Engineered 64kw heat transfer performance from each enclosure results with power density from 192kW (3 level) to 256kW (4 level) per one DCX Immersion Mining Rack. System hosts 30-40 MicroBT M56 Whatsminers, 36-48 M30/M50 Whatsminers or 24-32 Bitmain s19 Antminers in the single Immersion Mining Rack system within just 1 sq.m.

FEATURES

-

70% higher heat transfer performance than any other solution

-

Hosts new M56 / M50 and overclocked S19 miners.

-

30-40 x M56 miners per Immersion Rack

-

4MW and 720 miners – most powerful and affordable Immersion Mining Containers

PRO 10 Enclosure

The most effective immersion cooling tank in the world. Dedicated for new high-powered overclocked ASIC configurations, merging state-of-the art engineering, integrated sensors with TFT screen, remote temperature monitoring & reporting service, with up to 64 kW heat transfer from single enclosure. PRO10 Immersion Mining Enclosure can host up to 10 MicroBT M56 Whatsminers, 12 M30/M50 Whatsminers or 8 x Bitmain s19 Antminers.

In opposite to long tanks with multiple miners, small group of miners results in efficient cooling of overclocked ASICs including current and future models. The system embraces miner specific and replaceable internal components engineered to provide balanced flow and saturation of each device. Custom oversized plate heat exchanger / fittings and custom bigger pump result in low pressure drop and potential for system efficiency upgrades.

Proven, engineered, best in class 64kw heat transfer performance from each enclosure, and 192kW (3 level rack) to 256kW (4 level rack) in DCX Immersion Mining Rack. In the result of smart and efficient design ΔT of the system reaches from 20C to even 25C instead of 10C which is a generic in long tanks). System has been designed for heat reuse applications – elevated temperature set point (40C/104F inlet & 60C / 140F outlet) enables additional cost savings when purchasing heat rejection devices (dry coolers) and allows for sustainable and effective heat utilization for facility heating or different industrial applications. Higher set point temperatures also allow to plan efficient cooling of cryptomining operation in the hottest areas of the globe, including the Middle East ambient temperatures.

The system provides integrated TFT screen and full remote temperature monitoring & reporting service, cable management components for ethernet and power cable management as well as custom heat exchanger & silent pump integrated in every enclosure. Stackable in PRO10 Immersion Rack System, DCX PRO10 Immersion Enclosure can be installed in facility or high-density containers.

Technical Specification

FEATURES

-

70% higher heat transfer performance than any other solution

-

Hosts new M56 / M50 and overclocked S19 miners.

-

30-40 x M56 miners per Immersion Rack

-

4MW and 720 miners – most powerful and affordable Immersion Mining Containers

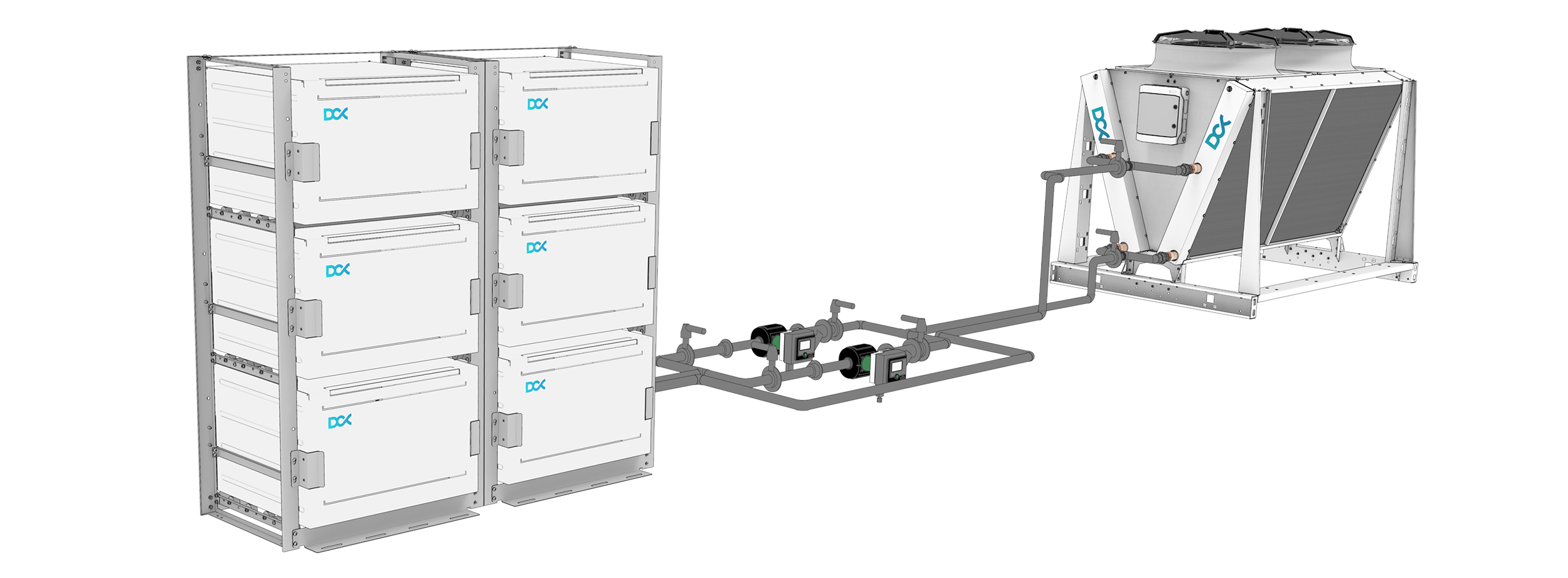

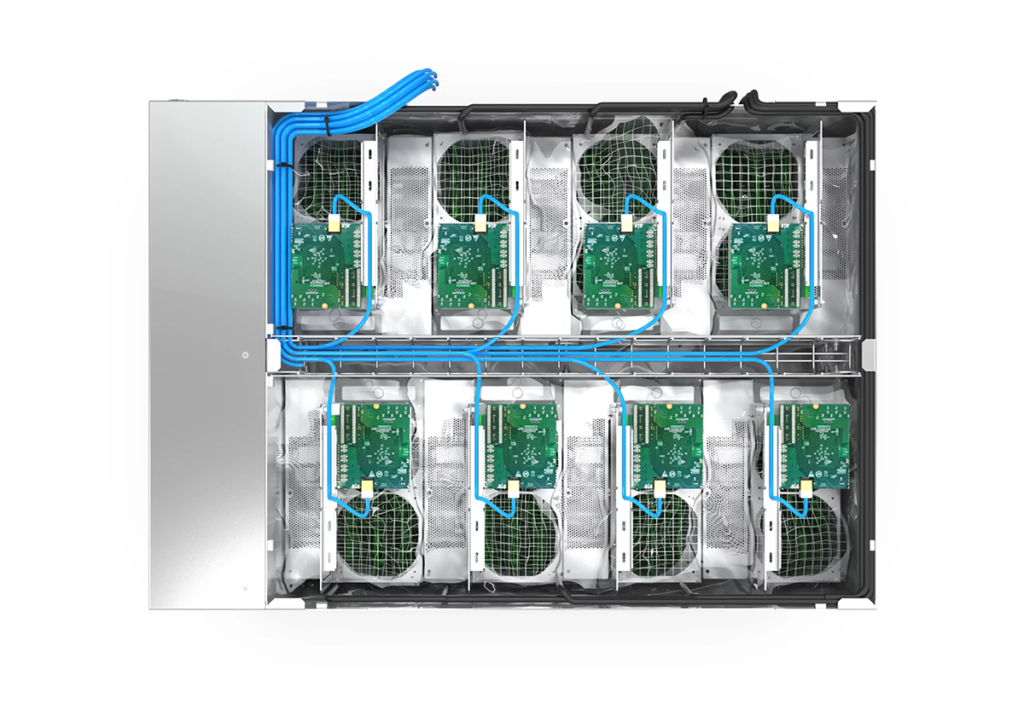

PRO 10 Immersion Rack

Two years ago, DCX pioneered introducing scalable and modular Immersion Enclosure & Immersion Rack System. New PRO10 Immersion Mining Rack has been engineered to provide industry best efficiency and density for new miner models. The rack type immersion cooling system, with a rated cooling capacity of 256kW consists of strong self-supporting rack frame with integrated high-capacity manifold and industrial tubing. Lids built info rack frame provide full protection for users and engineered fluid from dust, contamination, spill and UV.

The system is designed for installation in standard ISO container (from 2 to 4MW capacity per container) or to be installed in facility in datacenter-style multiple rows of immersion racks. Granular, dense build of multiple enclosures instead of long tanks results in the shortest connection to switchgear or transformer, enabling huge savings in power cabling & mitigating power loss. DCX PRO10 Immersion Mining Racks allow also for short connection to heat rejection device, simply hydraulic system topology, save fluid and piping cost, and lower pressure drop, resulting in most efficient cooling system.

Dual Immersion Mining Rack System has integrated manifolds and tubing – part of primary loop connecting the enclosure to heat rejection system. Both manifolds and industrial tubings have 2 x bigger diameters than any other cheap, knock-off rack systems. Rack frame has also mounting points for standard 0RU datacenter PDUs or high capacity DCX PDU systems. Power distribution cabling is separated from hydraulic tubing. Individual enclosures may be fully retracted from rack frame using maintenance platform for comfortable operation and servicing of the miners. This allows for flexible servicing, without disruption of mining process to provide easy and safe access to individual miner during maintenance.The system provides integrated temperature monitoring for each enclosure and for manifolds, if required.

Maintenance platform guarantees easy and safe access. Enclosure is fully retracted from rack frame for comfortable operation and servicing. Dimension of the rack frame: width: 2.3m / 7.4’ (dual rack); depth: 0.8m / 2.5’ (with fittings), height 3 level rack 1.7m / 5.4’ and 4 level rack – 2.2m / 7.1’

Technical Specification

FEATURES

-

70% higher heat transfer performance than any other solution

-

Hosts new M56 / M50 and overclocked S19 miners.

-

30-40 x M56 miners per Immersion Rack

-

4MW and 720 miners – most powerful and affordable Immersion Mining Containers

Quick intro

Unboxing of the Immersion Enclosure package and quick intro to the system components.

What you get – bundle

Enclosure with a 40kW dry cooler. We have a new ICP40 now, but you see what you get in the bundle package.

Installation & Startup

You bought the package – now what? Quick installation guide for effective commissioning of this smart immersion cooling system.

OVERVIEW

Two years ago, DCX pioneered introducing scalable and modular Immersion Enclosure & Immersion Rack System. Now being a global leader in liquid cooling solutions for the crypto mining industry, we offer a new generation of immersion systems – the PRO10 product line encompassing 3 platforms: PRO10 Immersion Mining Enclosure, PRO10 Immersion Mining Rack and PRO10 High Density Immersion Mining Container. We engineered this system from ground up to deliver heat transfer capacity, required by new miner types, including immersion miners as MicroBT M56 Whatsminer or significantly overclocked Bitmain Antminers. This performance positions DCX at the forefront of the rapidly expanding market.

DCX PRO10 Enclosure:

The most effective immersion cooling tank in the world. Dedicated for new high-powered overclocked ASIC configurations, merging state-of-the art engineering, integrated sensors with TFT screen, remote temperature monitoring & reporting service, with up to 64 kW heat transfer from single enclosure. PRO10 Immersion Mining Enclosure host up to 10 MicroBT M56 Whatsminers, 12 M30/M50 Whatsminers or 8 x Bitmain s19 Antminers. DCX Enclosure has been designed for heat reuse applications – elevated temperature set point enables sustainable and effective heat utilization. Efficient cooling allows crypto mining operation in the hottest areas of the globe, including the Middle East.

DCX PRO10 Rack System

Based on PRO10 Immersion Enclosures delivers up to 256 kW heat transfer from single Rack. PRO10 Immersion Mining Racks can be configured in rack groups in multi-MW installations, installed in facility or container system, delivering unmatched density and savings for a scale out mining operation. Engineered 64kw heat transfer performance from each enclosure results with power density from 192kW (3 level) to 256kW (4 level) per one DCX Immersion Mining Rack. System hosts 30-40 MicroBT M56 Whatsminers, 36-48 M30/M50 Whatsminers or 24-32 Bitmain s19 Antminers in the single Immersion Mining Rack system within just 1 sq.m.

FEATURES

-

70% higher heat transfer performance than any other solution

-

Hosts new M56 / M50 and overclocked S19 miners.

-

30-40 x M56 miners per Immersion Rack

-

4MW and 720 miners – most powerful and affordable Immersion Mining Containers

DCX IMMERSION

MINING CONTAINERS

The most powerful and most capablemining containers in the world

The most powerful and most capable Immersion Container: 4MW of heat rejection, 64 DCX PRO Enclosures | 640-720x Whatsminer M56 or 512-576x Bitmain S19 models

Complete 40ft mobile immersion system combined with 2 x 2 MW Immersion Optimized Dry coolers and complete primary and secondary hydraulic systems with optional or integrated switchgear system

OVERVIEW

Small but dense Immersion Crypto Mining Containers as DCX patent pending containerized system with immersion liquid cooling technology is the answer for all the problems that bother industry sized cryptocurrency mining farms. DCX Immersion Mining Containers solves all issues with proprietary, patent-pending granular Immersion Enclosure fluid distribution. The unmatched density of 700 to even 800 ASIC miners installed in immersion enclosures results in 2 to 4 MW power density. Each of our Immersion Containers is equipped with its own second loop pumping and heat exchange station. DCX’s second loop fluid distribution system circulates our ThermaSafe R dielectric Heat Transfer Fluid. Single-phase liquid has 1600 x better heat capacity and 4.5x better heat conductivity than air. Our fluid transports 100% of heat outside the enclosure and protects devices from the harsh environment and failure mechanisms including high temperature, humidity, vibration, corrosion, dust – major causes of electronic failures. Reduces thermal expansion cycling, maintains a constant temperature, eliminates airborne contaminants, and failures due to zinc and tin whisker growth. ThermaSafe R works also as a fire suppressant making sure you are protected even in remote mining operations.

Based on the DCX Scale Out PRO10 Immersion Enclosures and Immersion Rack Systems, PRO10 HD container includes a complete hydraulic system. Containers are available with maximized miners density (all rack build) or with Low Power Switchgear components to be built-in within the container frame. Available in standard 20HC or 40HC ISO format, easy to transport and commissioning at any destination, PRO10 HD containers are based on standard ISO container and hold CSC certification. System can be delivered with:

- complete immersion cooling system with hydraulic loop and standard adaptations & wiring built-in, to be later integrated with switchgear option at investor site,

- turnkey solution including switchgear, power distribution and all options and accessories for region specific (UL / CE / ELTEK) certification.

System capacity:

- – 20HC: 2MW Heat Transfer Capacity 256 x S19 / 320 x M56 / 384 x M30

- – 40HC: 4MW Heat Transfer Capacity 576 x S19 / 720 x M56 / 864 x M30

System density options:

- DCX 20HC: 2MW Heat Transfer Performance – 256 x S19 / 320 x M56 / 384 x M30

- DCX 20HC-PD: 1.7 MW Heat Transfer Performance. Turnkey system with full power distribution (switchgear) and accessories included – 192 x S19 / 240 x M56 / 288 x M30

- DCX 40HC: 4MW Heat Transfer Performance – 576 x S19 / 720 x M56 / 864 x M30

- DCX 40HC-PD: 4MW Heat Transfer Performance. Turnkey system with full power distribution (switchgear) and accessories included – 512 x S19 / 640 x M56 / 768 x M30

FEATURES

-

70% higher heat transfer performance than any other solution

-

Hosts new M56 / M50 and overclocked S19 miners.

-

30-40 x M56 miners per Immersion Rack

-

4MW and 720 miners – most powerful and affordable Immersion Mining Containers

| Form Factor ISO Standard | 20HC 3L | 20HC 4L | 20HC PD 3L | 20HC PD 4L | 40HC 3L | 40HC 4L | 40HC PD 3L | 40HC PD 4L | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Primary Loop Hydraulic System | Built-in | Built-in | Built-in | Built-in | Built-in | Built-in | Built-in | Built-in | |||||||

| Dual Side Access | Included | Included | Included | Included | Included | Included | Included | Included | |||||||

| Power and Ethernet Cable Tray | Included | Included | Included | Included | Included | Included | Included | Included | |||||||

| Led Lighting | Included | Included | Included | Included | Included | Included | Included | Included | |||||||

| Ventilation / Exhaust Fans | Included | Included | Included | Included | Included | Included | Included | Included | |||||||

| Grounding & Lightning protection | Included | Included | Included | Included | Included | Included | Included | Included | |||||||

| 1P Internal Power Cabling | Built-in | Built-in | Built-in | Built-in | Built-in | Built-in | Built-in | Built-in | |||||||

| 3P Miner Power Cabling | Not included | Not included | Not included | Included | Not included | Not included | Included | Included | |||||||

| Main Power Switchgear | Not included | Not included | Included | Included | Not included | Not included | Included | Included | |||||||

| PDUs | Not included | Not included | Included | Included | Not included | Not included | Included | Included | |||||||

| Aggregation Switches & cabling | Not included | Not included | Included | Included | Not included | Not included | Included | Included | |||||||

| Rack Frames | 8 | 8 | 6 | 2*3 | 18 | 18 | 14 | 16 | |||||||

| Pro10 Enclosures | 24 | 32 | 18 | 24 | 54 | 72 | 42 | 64 | |||||||

| Max. Enclure heat transfer (kW) | 64 | 64 | 64 | 64 | 64 | 64 | 64 | 64 | |||||||

| Thermasafe R Volume (L) | 5280 | 7040 | 3960 | 5280 | 11880 | 15840 | 9240 | 14080 | |||||||

| Miner Qty. S19 form factor | 192 | 256 | 144 | 192 | 432 | 576 | 336 | 512 | |||||||

| Miner Qty. M56 form factor | 240 | 320 | 180 | 240 | 540 | 720 | 420 | 640 | |||||||

| Miner Qty. M30 form factor | 288 | 384 | 216 | 288 | 648 | 864 | 504 | 768 | |||||||

| Max. Power S19 (kW) | 8 | 8 | 8 | 8 | 8 | 7 | 8 | 8 | |||||||

| Max. Power M56 (kW) | 7 | 6.4 | 7 | 7 | 7 | 5.5 | 7 | 6.25 | |||||||

| Heat Transfer Capacity S19 (kW) | 1536 | 2048 | 1152 | 1536 | 3456 | 4032 | 2688 | 4096 | |||||||

| Heat Transfer Capacity M56 (kW) | 1680 | 2048 | 1260 | 1680 | 3780 | 3960 | 2940 | 4000 | |||||||

| Actual Heat Transfer Capacity | 1,7 MW | 2 MW | 1,2 MW | 1,7 MW | 3,8 MW | 4 MW | 3 MW | 4 MW | |||||||

| Maximum Heat Transfer Capacity | 2 MW | 2 MW | 2 MW | 2 MW | 4 MW | 4 MW | 4 MW | 4 MW | |||||||

| Primary Operating Power (kW) | 5.4 | 9.3 | 3.8 | 6.4 | 14.7 | 19.7 | 10.2 | 16 | |||||||

| Total Operating Power (kW) | 12.62 | 18.76 | 9.34 | 13.62 | 30.32 | 40.36 | 22.46 | 34.42 | |||||||

| Primary Loop Temperatures | Supply 20-40°C | Return 40-60°C | ||||||||||||||

| Ambient Operation Temperature | -5°C~40°C | ||||||||||||||

| Input voltage | 3P 380-440V 50/60HZ | 1P 220V or 230V 50/60H | ||||||||||||||

| Certification | CE | ||||||||||||||

| Primary Loop Monitoring & Control | Remote monitoring & control: Flow, Temperatures, High Availability control and automatic switchover | ||||||||||||||

| Enclosure Monitoring | Remote monitoring: Individual Temperature, Power, Heat Transfer, Alarms | 2.4" OLED TFT | ||||||||||||||

| PDU (if included) | Remote monitoring & control: Power, Voltage, Alarms, Reset | ||||||||||||||

| Container System | Invidual temperature and humidity control, CCTV optional | ||||||||||||||

| Dry Cooler System | Supply Return Temperatures, Alarms, Fan Status, Current Power | ||||||||||||||

20HC IMMERSION MINING CONTAINER

Based on the DCX Scale Out PRO10 Immersion Enclosures and Immersion Rack Systems, they include a complete hydraulic system. Containers are available with maximized miners density (all rack build) or with Low Power Switchgear components to be built-in within the container frame.

- Heat transfer capacity: 2MW Heat Transfer Capacity

- Miner capacity: 256 x S19 / 320 x M56 / 384 x M30

System density options:

- DCX 20HC: 2MW Heat Transfer Performance – 256 x S19 / 320 x M56 / 384 x M30

- DCX 20HC-PD: 1.7 MW Heat Transfer Performance. Turnkey system with full power distribution (switchgear) and accessories included – 192 x S19 / 240 x M56 / 288 x M30

Technical Specification

| Form Factor ISO Standard | 20HC 3L | 20HC 4L | 20HC PD 3L | 20HC PD 4L |

|---|---|---|---|---|

| Primary Loop Hydraulic System | Built-in | Built-in | Built-in | Built-in |

| Dual Side Access | Included | Included | Included | Included |

| Power and Ethernet Cable Tray | Included | Included | Included | Included |

| Led Lighting | Included | Included | Included | Included |

| Ventilation / Exhaust Fans | Included | Included | Included | Included |

| Grounding & Lightning protection | Included | Included | Included | Included |

| 1P Internal Power Cabling | Built-in | Built-in | Built-in | Built-in |

| 3P Miner Power Cabling | Not included | Not included | Included | Included |

| Main Power Switchgear | Not included | Not included | Included | Included |

| PDUs | Not included | Not included | Included | Included |

| Aggregation Switches & cabling | Not included | Not included | Included | Included |

| Rack Frames | 8 | 8 | 6 | 6 |

| Pro10 Enclosures | 24 | 32 | 18 | 24 |

| Max. Enclure heat transfer (kW) | 64 | 64 | 64 | 64 |

| Thermasafe R Volume (L) | 5280 | 7040 | 3960 | 5280 |

| Miner Qty. S19 form factor | 192 | 256 | 144 | 192 |

| Miner Qty. M56 form factor | 240 | 320 | 180 | 240 |

| Miner Qty. M30 form factor | 288 | 384 | 216 | 288 |

| Max. Power S19 (kW) | 8 | 8 | 8 | 8 |

| Max. Power M56 (kW) | 7 | 6,4 | 7 | 7 |

| Heat Transfer Capacity S19 (kW) | 1536 | 2048 | 1152 | 1536 |

| Heat Transfer Capacity M56 (kW) | 1680 | 2048 | 1260 | 1680 |

| Actual Heat Transfer Capacity | 1,7 MW | 2 MW | 1,2 MW | 1,7 MW |

| Maximum Heat Transfer Capacity | 2 MW | 2 MW | 2 MW | 2 MW |

| Primary Operating Power (kW) | 5,4 | 9,3 | 3,8 | 6,4 |

| Total Operating Power (kW) | 12,62 | 18,76 | 9,34 | 13,62 |

| Primary Loop Temperatures | Supply 20-40°C | Return 40-60°C | |||

| Ambient Operation Temperature | -5°C~40°C | |||

| Input voltage | 3P 380-440V 50/60HZ | 1P 220V or 230V 50/60H | |||

| Certification | CE | |||

| Primary Loop Monitoring & Control | Remote monitoring & control: Flow, Temperatures, High Availability control and automatic switchover | |||

| Enclosure Monitoring | Remote monitoring: Individual Temperature, Power, Heat Transfer, Alarms | 2.4" OLED TFT | |||

| PDU (if included) | Remote monitoring & control: Power, Voltage, Alarms, Reset | |||

| Container System | Invidual temperature and humidity control, CCTV optional | |||

| Dry Cooler System | Supply Return Temperatures, Alarms, Fan Status, Current Power |

FEATURES

-

70% higher heat transfer performance than any other solution

-

Hosts new M56 / M50 and overclocked S19 miners.

-

30-40 x M56 miners per Immersion Rack

-

4MW and 720 miners – most powerful and affordable Immersion Mining Containers

40HC IMMERSION MINING CONTAINER

4MW Immersion Container – complete 40ft mobile immersion system combined with 2 x 2 MW Immersion Optimized Dry coolers, complete primary and secondary hydraulic systems and 4MW switchgear / power distribution subsystem.

- Heat transfer capacity: up to 4MW Heat Transfer Capacity

- Miner capacity: 576 x S19 / 720 x M56 / 864 x M30

System density options:

- DCX 40HC: 4MW Heat Transfer Performance – 576 x S19 / 720 x M56 / 864 x M30

- DCX 40HC-PD: 4MW Heat Transfer Performance. Turnkey system with full power distribution (switchgear) and accessories included – 512 x S19 / 640 x M56 / 768 x M30

Technical Specification

| Form Factor ISO Standard | 40HC 3L | 40HC 4L | 40HC PD 3L | 40HC PD 4L |

|---|---|---|---|---|

| Primary Loop Hydraulic System | Built-in | Built-in | Built-in | Built-in |

| Dual Side Access | Included | Included | Included | Included |

| Power and Ethernet Cable Tray | Included | Included | Included | Included |

| Led Lighting | Included | Included | Included | Included |

| Ventilation / Exhaust Fans | Included | Included | Included | Included |

| Grounding & Lightning protection | Included | Included | Included | Included |

| 1P Internal Power Cabling | Built-in | Built-in | Built-in | Built-in |

| 3P Miner Power Cabling | Not included | Not included | Included | Included |

| Main Power Switchgear | Not included | Not included | Included | Included |

| PDUs | Not included | Not included | Included | Included |

| Aggregation Switches & cabling | Not included | Not included | Included | Included |

| Rack Frames | 18 | 18 | 14 | 16 |

| Pro10 Enclosures | 54 | 72 | 42 | 64 |

| Max. Enclure heat transfer (kW) | 64 | 64 | 64 | 64 |

| Thermasafe R Volume (L) | 11880 | 15840 | 9240 | 14080 |

| Miner Qty. S19 form factor | 432 | 576 | 336 | 512 |

| Miner Qty. M56 form factor | 540 | 720 | 420 | 640 |

| Miner Qty. M30 form factor | 648 | 864 | 504 | 768 |

| Max. Power S19 (kW) | 8 | 7 | 8 | 8 |

| Max. Power M56 (kW) | 7 | 5,5 | 7 | 6,25 |

| Heat Transfer Capacity S19 (kW) | 3456 | 4032 | 2688 | 4096 |

| Heat Transfer Capacity M56 (kW) | 3780 | 3960 | 2940 | 4000 |

| Actual Heat Transfer Capacity | 3,8 MW | 4 MW | 3 MW | 4 MW |

| Maximum Heat Transfer Capacity | 4 MW | 4 MW | 4 MW | 4 MW |

| Primary Operating Power (kW) | 14,7 | 19,7 | 10,2 | 16 |

| Total Operating Power (kW) | 30,32 | 40,36 | 22,46 | 34,42 |

| Primary Loop Temperatures | Supply 20-40°C | Return 40-60°C | |||

| Ambient Operation Temperature | -5°C~40°C | |||

| Input voltage | 3P 380-440V 50/60HZ | 1P 220V or 230V 50/60H | |||

| Certification | CE | |||

| Primary Loop Monitoring & Control | Remote monitoring & control: Flow, Temperatures, High Availability control and automatic switchover | |||

| Enclosure Monitoring | Remote monitoring: Individual Temperature, Power, Heat Transfer, Alarms | 2.4" OLED TFT | |||

| PDU (if included) | Remote monitoring & control: Power, Voltage, Alarms, Reset | |||

| Container System | Invidual temperature and humidity control, CCTV optional | |||

| Dry Cooler System | Supply Return Temperatures, Alarms, Fan Status, Current Power |

FEATURES

-

70% higher heat transfer performance than any other solution

-

Hosts new M56 / M50 and overclocked S19 miners.

-

30-40 x M56 miners per Immersion Rack

-

4MW and 720 miners – most powerful and affordable Immersion Mining Containers

Quick intro

Unboxing of the Immersion Enclosure package and quick intro to the system components.

What you get – bundle

Enclosure with a 40kW dry cooler. We have a new ICP40 now, but you see what you get in the bundle package.

Installation & Startup

You bought the package – now what? Quick installation guide for effective commissioning of this smart immersion cooling system.

The most powerful and most capable Immersion Container: 4MW of heat rejection, 64 DCX PRO Enclosures | 640-720x Whatsminer M56 or 512-576x Bitmain S19 models

Complete 40ft mobile immersion system combined with 2 x 2 MW Immersion Optimized Dry coolers and complete primary and secondary hydraulic systems with optional or integrated switchgear system

OVERVIEW

Small but dense Immersion Crypto Mining Containers as DCX patent pending containerized system with immersion liquid cooling technology is the answer for all the problems that bother industry sized cryptocurrency mining farms. DCX Immersion Mining Containers solves all issues with proprietary, patent-pending granular Immersion Enclosure fluid distribution. The unmatched density of 700 to even 800 ASIC miners installed in immersion enclosures results in 2 to 4 MW power density. Each of our Immersion Containers is equipped with its own second loop pumping and heat exchange station. DCX’s second loop fluid distribution system circulates our ThermaSafe R dielectric Heat Transfer Fluid. Single-phase liquid has 1600 x better heat capacity and 4.5x better heat conductivity than air. Our fluid transports 100% of heat outside the enclosure and protects devices from the harsh environment and failure mechanisms including high temperature, humidity, vibration, corrosion, dust – major causes of electronic failures. Reduces thermal expansion cycling, maintains a constant temperature, eliminates airborne contaminants, and failures due to zinc and tin whisker growth. ThermaSafe R works also as a fire suppressant making sure you are protected even in remote mining operations.

Based on the DCX Scale Out PRO10 Immersion Enclosures and Immersion Rack Systems, PRO10 HD container includes a complete hydraulic system. Containers are available with maximized miners density (all rack build) or with Low Power Switchgear components to be built-in within the container frame. Available in standard 20HC or 40HC ISO format, easy to transport and commissioning at any destination, PRO10 HD containers are based on standard ISO container and hold CSC certification. System can be delivered with:

- complete immersion cooling system with hydraulic loop and standard adaptations & wiring built-in, to be later integrated with switchgear option at investor site,

- turnkey solution including switchgear, power distribution and all options and accessories for region specific (UL / CE / ELTEK) certification.

System capacity:

- – 20HC: 2MW Heat Transfer Capacity 256 x S19 / 320 x M56 / 384 x M30

- – 40HC: 4MW Heat Transfer Capacity 576 x S19 / 720 x M56 / 864 x M30

System density options:

- DCX 20HC: 2MW Heat Transfer Performance – 256 x S19 / 320 x M56 / 384 x M30

- DCX 20HC-PD: 1.7 MW Heat Transfer Performance. Turnkey system with full power distribution (switchgear) and accessories included – 192 x S19 / 240 x M56 / 288 x M30

- DCX 40HC: 4MW Heat Transfer Performance – 576 x S19 / 720 x M56 / 864 x M30

- DCX 40HC-PD: 4MW Heat Transfer Performance. Turnkey system with full power distribution (switchgear) and accessories included – 512 x S19 / 640 x M56 / 768 x M30

FEATURES

-

70% higher heat transfer performance than any other solution

-

Hosts new M56 / M50 and overclocked S19 miners.

-

30-40 x M56 miners per Immersion Rack

-

4MW and 720 miners – most powerful and affordable Immersion Mining Containers

HYDRO COOLING SYSTEMS

Dual loop, condensation safe hydro cooling

OVERVIEW

DCX offers a full range of cost-effective but enterprise class Coolant Distribution Units (CDUs) for hydro miners and direct liquid cooling system which support advanced and power hungry hydro miner models. We propose multiple CDU systems designed to fulfil specific requirements from small scale to large liquid cooling operations, including the in-rack CDU 1 & 2 models, as well as CDU 3, 6, 9, and 12 with a rated capacity from 300kW to 1200kW per single CDU system. These CDU’s are designed for high-powered miners or mining servers and offer advanced features such as variable-speed pumps, full condensation control, cooling loop separation, redundant components, adaptive operation, energy efficient cooling & intelligent controls with full remote control of the system.

DCX CDU’s, are a standalone, rack based Coolant Distribution Units (CDU), a key component in direct chip cooling (DLC) or hydro cooling systems. Those CDU’s with a rated cooling capacity from 300 to 1200 kW offer adaptive and efficient cooling of hydro miners with full condensation control. The CDU’s are designed to regulate the flow and temperature of coolant and ensure that each component in the cooling loop receives an adequate supply of flow to maintain the desired operating temperature. It is also responsible for monitoring the temperature of the coolant and adjusting the flow rate as necessary to maintain the temperature below the dew point protecting the precious electronics from condensation. DCX CDU’s provides effective separation of the facility circuit and secondary circuit which allows controlled fluid quality and ensures that the cooling fluid in a data centre environment can be kept to a minimum volume, is closely controlled for flow, pressure & temperature and can be accurately maintained for fluid quality.

Some of the key features of a DCX CDU’s include:

- High flow rate: designed to deliver a high flow rate of coolant to ensure that each component in the cooling loop receives an adequate supply of coolant.

- Full remote monitoring: contains temperature, flow and operation sensors that monitor the temperature of the coolant and adjust the flow rate as necessary to maintain a consistent temperature.

- Redundancy: designed with redundant pumps and other components to ensure that the cooling system remains operational in the event of a failure.

- Energy efficiency: CDU’s are designed to be energy-efficient, with features such as variable speed pumps and advanced control systems that help to minimize energy consumption.

Overall, our Coolant Distribution Units play a critical role in the operation of direct liquid cooling systems and hydro systems in data centres, helping to maintain the desired operating temperature and ensure the reliability and efficiency of the cooling system.

FEATURES

-

Enterprise class system & controls with full redundancy

-

Complete loop separation and condensation control

-

From 300kw to 1.2MW per single CDU

-

From 6 to 28 server racks per single CDU

CDU 3 – Liquid to Liquid Cooling Distribution Unit

DCX offers a full range of cost-effective but enterprise class Coolant Distribution Units (CDUs) for hydro miners and direct liquid cooling systems, including the in-rack CDU 1 & 2 models, as well as CDU 3, 6, 9, and 12 with a rated capacity from 300kW to 1200kW per single CDU system. These CDUs are designed for high-powered miners or mining servers and offer advanced features such as variable-speed pumps, full condensation control, cooling loop separation, redundant components, adaptive operation, energy efficient cooling & intelligent controls with full remote control of the system.

DCX CDU 3, a standalone, rack based Coolant Distribution Unit (CDU), is a key component in direct chip cooling (DLC) or hydro cooling systems. This CDU unit with a rated cooling capacity of 300kW offers adaptive and efficient cooling of hydro miners with full condensation control. The CDU is designed to regulate the flow and temperature of coolant and ensure that each component in the cooling loop receives an adequate supply of flow to maintain the desired operating temperature. It is also responsible for monitoring the temperature of the coolant and adjusting the flow rate as necessary to maintain the temperature below the dew point protecting the precious electronics from condensation. DCX CDU 3 provides effective separation of the facility circuit and secondary circuit which allows controlled fluid quality and ensures that the cooling fluid in a data centre environment can be kept to a minimum volume, is closely controlled for flow, pressure & temperature and can be accurately maintained for fluid quality.

Dual pump highly redundant design. It can be maintained without shutting down when the pump/power fails or the filter is clogged. The system has a comprehensive real-time monitoring function of operating parameters. The communication interface of upper computer adopts 2 redundant RS485 & 2 redundant RJ45, and the default communication protocol Modbus RTU & Modbus TCP/IP. Also it can be customized and modified according to the customer requirements.

General Spec

| 1 | 2 |

|---|---|

| Cooling Capacity | >300kW@AT=15℃ |

| Primary Coolant | ASHRAE W4 (45℃) facility liquid |

| AC Power | 3P AC380V±10% 50/60Hz |

| Power Consumption | 4kW |

| Dimension | 600*1200*2035 (W*D*H) |

| Transport / wqwWet Weight | 450/560 kg |

Technical Specification

| Rated cooling capacity (kW) | 300 | ||||||

| Operation condition description | Working condition 1 | Working condition 2 | |||||

| Primary side | Secondary side | Primary side | Secondary side | ||||

| Coolant | DI-water | DI-water | PG-25 | PG-25 | |||

| Flow (m3/h) | 18.9 | 18.9 | 18.9 | 18.9 | |||

| Output rated dP (bar) | / | ≥7.2/0.5 | / | ≥7.2/0.5 | |||

| Rated inlet temperature (°C) | 36 | 58.7 | 35 | 59.9 | |||

| Rated outlet temperature (°C ) | 49.7 | 45 | 49.9 | 49.9 | |||

| Cooling capacity margin | 23% | 19% | |||||

| Height (mm) | Width (mm) | Depth (mm) | 2280 | 900 | 1300 | ||||||

| Transport weight (kg / lbs) | 970 / 2138 | 1065 / 2348 | |||||

| Operation weight (kg / lbs) | 1180/ 2601 | 1370 / 3020 | |||||

| Max. power (kW) | 4 kW | ||||||

| T-V coefficient (C*L) | 3.2×104 | ||||||

| Power specifications | 3P AC380V 50/60Hz | ||||||

| Working environment T&H | 0~50°/ RH5~85% | ||||||

| Noise Level | 65dB(A) | ||||||

FEATURES

-

Enterprise class system & controls with full redundancy

-

Complete loop separation and condensation control

-

From 300kw to 1.2MW per single CDU

-

From 6 to 28 server racks per single CDU

CDU 6 – Liquid to Liquid Cooling Distribution Unit

DCX offers a full range of cost-effective but enterprise class Coolant Distribution Units (CDUs) for hydro miners and direct liquid cooling systems, including the in-rack CDU 1 & 2 models, as well as CDU 3, 6, 9, and 12 with a rated capacity from 300kW to 1200kW per single CDU system. These CDUs are designed for high-powered miners or mining servers and offer advanced features such as variable-speed pumps, full condensation control, cooling loop separation, redundant components, adaptive operation, energy efficient cooling & intelligent controls with full remote control of the system.

DCX CDU 6, a standalone, rack based Coolant Distribution Unit (CDU), is a key component in direct chip cooling (DLC) or hydro cooling systems. This CDU unit with a rated cooling capacity of 600kW offers adaptive and efficient cooling of hydro miners with full condensation control. The CDU is designed to regulate the flow and temperature of coolant and ensure that each component in the cooling loop receives an adequate supply of flow to maintain the desired operating temperature. It is also responsible for monitoring the temperature of the coolant and adjusting the flow rate as necessary to maintain the temperature below the dew point protecting the precious electronics from condensation. DCX CDU 6 provides effective separation of the facility circuit and secondary circuit which allows controlled fluid quality and ensures that the cooling fluid in a data centre environment can be kept to a minimum volume, is closely controlled for flow, pressure & temperature and can be accurately maintained for fluid quality.

Dual pump highly redundant design. It can be maintained without shutting down when the pump/power fails or the filter is clogged. The system has a comprehensive real-time monitoring function of operating parameters. The communication interface of upper computer adopts 2 redundant RS485 & 2 redundant RJ45, and the default communication protocol Modbus RTU & Modbus TCP/IP. Also it can be customized and modified according to the customer requirements.

General Spec

| 1 | 2 |

|---|---|

| Cooling Capacity | 600kW@AT=15℃ |

| Primary Coolant | ASHRAE W4 (45℃) facility liquid |

| AC Power | 3P AC380V±10% 50/60Hz |

| Power Consumption | 7-11kW |

| Dimension | 900*1300*2280 (W*D*H) |

| Transport / wqwWet Weight | 1180/1370 kg |

Technical Specification

| Rated cooling capacity (kW) | IB600****AT10 | ||||||

|---|---|---|---|---|---|---|---|

| Product Model | IB600****AT10 | IB600****AT10 | |||||

| Operation condition | Primary side | Secondary side | Primary side | Secondary side | |||

| Coolant | Facility-water | DI-water | Facility-water | DI-water | |||

| Flow (m3/h) | 35 | 35 | 35 | 35 | |||

| Output rated dP (bar) | / | ≥2.8 | / | ≥3.2 | |||

| Rated inlet temperature (°C) | 35 | 65 | 35 | 52.7 | |||

| Rated outlet temperature (°C ) | 50 | 45 | 49.6 | 38 | |||

| Cooling capacity margin | 20% | -1.5% | |||||

| Height (mm) | Width (mm) | Depth (mm) | 2280 | 900 | 1300 | ||||||

| Transport weight (kg / lbs) | 970 / 2138 | 1065 / 2348 | |||||

| Operation weight (kg / lbs) | 1180/ 2601 | 1370 / 3020 | |||||

| Max. power (kW) | 7 (Pump3004) / 11 (Pump4604) | ||||||

| T-V coefficient (C*L) | 4.8×104 | ||||||

| Power specifications | 3P AC380V 50/60Hz | ||||||

| Working environment T&H | 0~50°/ RH5~85% | ||||||

| Noise Level | 65dB(A) | ||||||

FEATURES

-

Enterprise class system & controls with full redundancy

-

Complete loop separation and condensation control

-

From 300kw to 1.2MW per single CDU

-

From 6 to 28 server racks per single CDU

CDU 9 – Liquid to Liquid Cooling Distribution Unit

DCX offers a full range of cost-effective but enterprise class Coolant Distribution Units (CDUs) for hydro miners and direct liquid cooling systems, including the in-rack CDU 1 & 2 models, as well as CDU 3, 6, 9, and 12 with a rated capacity from 300kW to 1200kW per single CDU system. These CDUs are designed for high-powered miners or mining servers and offer advanced features such as variable-speed pumps, full condensation control, cooling loop separation, redundant components, adaptive operation, energy efficient cooling & intelligent controls with full remote control of the system.

DCX CDU 9, a standalone, rack based Coolant Distribution Unit (CDU), is a key component in direct chip cooling (DLC) or hydro cooling systems. This CDU unit with a rated cooling capacity of 900kW offers adaptive and efficient cooling of hydro miners with full condensation control. The CDU is designed to regulate the flow and temperature of coolant and ensure that each component in the cooling loop receives an adequate supply of flow to maintain the desired operating temperature. It is also responsible for monitoring the temperature of the coolant and adjusting the flow rate as necessary to maintain the temperature below the dew point protecting the precious electronics from condensation. DCX CDU 9 provides effective separation of the facility circuit and secondary circuit which allows controlled fluid quality and ensures that the cooling fluid in a data centre environment can be kept to a minimum volume, is closely controlled for flow, pressure & temperature and can be accurately maintained for fluid quality.

Dual pump highly redundant design. It can be maintained without shutting down when the pump/power fails or the filter is clogged. The system has a comprehensive real-time monitoring function of operating parameters. The communication interface of upper computer adopts 2 redundant RS485 & 2 redundant RJ45, and the default communication protocol Modbus RTU & Modbus TCP/IP. Also it can be customized and modified according to the customer requirements.

General Spec

| 1 | 2 |

|---|---|

| Cooling Capacity | 900kW@AT=15℃ |

| Primary Coolant | ASHRAE W4 (45℃) facility liquid |

| AC Power | 3P AC380V±10% 50/60Hz |

| Power Consumption | 11kW |

| Dimension | 9500*1500*2213 (W*D*H) |

| Transport / wqwWet Weight | 1390/1610 kg |

Technical Specification

| Rated cooling capacity (kW) | IB600****AT10 | ||||||

|---|---|---|---|---|---|---|---|

| Rated cooling capacity (kW) | 900 | ||||||

| Product Model | IB900****AT10 | IB900****AT03 | |||||

| Operation condition | Primary side | Secondary side | Primary side | Secondary side | |||

| Coolant | Facility-water | DI-water | Facility-water | DI-water | |||

| Flow (m3/h) | 52 | 52 | 52 | 52 | |||

| Output rated dP (bar) | / | ≥2.8 | / | ≥3.2 | |||

| Rated inlet temperature (°C) | 35 | 63.1 | 35 | 52.8 | |||

| Rated outlet temperature (°C ) | 53 | 45 | 49.8 | 38 | |||

| Cooling capacity margin | 20% | -1.5% | |||||

| Height (mm) | Width (mm) | Depth (mm) | 2035 | 600 | 1200 | ||||||

| Transport weight (kg / lbs) | 1090 / 2403 | 1223 / 2696 | |||||

| Operation weight (kg / lbs) | 1390 / 3064 | 1610 / 3549 | |||||

| Max. power (kW) | 11 | ||||||

| T-V coefficient (C*L) | 4.8×104 | ||||||

| Power specifications | 3P AC380V 50/60Hz | ||||||

| Working environment T&H | 0~50°/ RH5~85% | ||||||

| Noise Level | 65dB(A) | ||||||

FEATURES

-

Enterprise class system & controls with full redundancy

-

Complete loop separation and condensation control

-

From 300kw to 1.2MW per single CDU

-

From 6 to 28 server racks per single CDU

CDU 12 – Liquid to Liquid Cooling Distribution Unit

DCX offers a full range of cost-effective but enterprise class Coolant Distribution Units (CDUs) for hydro miners and direct liquid cooling systems, including the in-rack CDU 1 & 2 models, as well as CDU 3, 6, 9, and 12 with a rated capacity from 300kW to 1200kW per single CDU system. These CDUs are designed for high-powered miners or mining servers and offer advanced features such as variable-speed pumps, full condensation control, cooling loop separation, redundant components, adaptive operation, energy efficient cooling & intelligent controls with full remote control of the system.

DCX CDU 12, a standalone, rack based Coolant Distribution Unit (CDU), is a key component in direct chip cooling (DLC) or hydro cooling systems. This CDU unit with a rated cooling capacity of 1200kW offers adaptive and efficient cooling of hydro miners with full condensation control. The CDU is designed to regulate the flow and temperature of coolant and ensure that each component in the cooling loop receives an adequate supply of flow to maintain the desired operating temperature. It is also responsible for monitoring the temperature of the coolant and adjusting the flow rate as necessary to maintain the temperature below the dew point protecting the precious electronics from condensation. DCX CDU 12 provides effective separation of the facility circuit and secondary circuit which allows controlled fluid quality and ensures that the cooling fluid in a data centre environment can be kept to a minimum volume, is closely controlled for flow, pressure & temperature and can be accurately maintained for fluid quality.

Dual pump highly redundant design. It can be maintained without shutting down when the pump/power fails or the filter is clogged. The system has a comprehensive real-time monitoring function of operating parameters. The communication interface of upper computer adopts 2 redundant RS485 & 2 redundant RJ45, and the default communication protocol Modbus RTU & Modbus TCP/IP. Also it can be customized and modified according to the customer requirements.

General Spec

| 1 | 2 |

|---|---|

| Cooling Capacity | >1200kW@AT=15℃ |

| Primary Coolant | ASHRAE W4 (45℃) facility liquid |

| AC Power | 3P AC380V±10% 50/60Hz |

| Power Consumption | 13kW |

| Dimension | 950*1500*2265 (W*D*H) |

| Transport / wqwWet Weight | 1600/1850 kg |

Technical Specification

| Rated cooling capacity (kW) | IB600****AT10 | ||||||

|---|---|---|---|---|---|---|---|

| Rated cooling capacity (kW) | 1200 | ||||||

| Product Model | IB1200****AT10 | IB1200****AT03 | |||||

| Operation condition | Primary side | Secondary side | Primary side | Secondary side | |||

| Coolant | Facility-water | DI-water | Facility-water | DI-water | |||

| Flow (m3/h) | 73 | 73 | 73 | 73 | |||

| Output rated dP (bar) | / | ≥2.0 | / | ≥2.0 | |||

| Rated inlet temperature (°C) | 35 | 59.3 | 35 | 52.8 | |||

| Rated outlet temperature (°C ) | 53 | 45 | 49.8 | 38 | |||

| Cooling capacity margin | 28% | 4% | |||||

| Height (mm) | Width (mm) | Depth (mm) | 2265 | 950 | 1500 | ||||||

| Transport weight (kg / lbs) | 1600 / 3527.4 | 1745 / 3847 | |||||

| Operation weight (kg / lbs) | 1850 / 4078.6 | 2019 / 4451 | |||||

| Max. power (kW) | 13 | ||||||

| T-V coefficient (C*L) | 6.4×104 | ||||||

| Power specifications | 3P AC380V 50/60Hz | ||||||

| Working environment T&H | 0~50°/ RH5~85% | ||||||

| Noise Level | 65dB(A) | ||||||

FEATURES

-

Enterprise class system & controls with full redundancy

-

Complete loop separation and condensation control

-

From 300kw to 1.2MW per single CDU

-

From 6 to 28 server racks per single CDU

OVERVIEW

DCX offers a full range of cost-effective but enterprise class Coolant Distribution Units (CDUs) for hydro miners and direct liquid cooling system which support advanced and power hungry hydro miner models. We propose multiple CDU systems designed to fulfil specific requirements from small scale to large liquid cooling operations, including the in-rack CDU 1 & 2 models, as well as CDU 3, 6, 9, and 12 with a rated capacity from 300kW to 1200kW per single CDU system. These CDU’s are designed for high-powered miners or mining servers and offer advanced features such as variable-speed pumps, full condensation control, cooling loop separation, redundant components, adaptive operation, energy efficient cooling & intelligent controls with full remote control of the system.

DCX CDU’s, are a standalone, rack based Coolant Distribution Units (CDU), a key component in direct chip cooling (DLC) or hydro cooling systems. Those CDU’s with a rated cooling capacity from 300 to 1200 kW offer adaptive and efficient cooling of hydro miners with full condensation control. The CDU’s are designed to regulate the flow and temperature of coolant and ensure that each component in the cooling loop receives an adequate supply of flow to maintain the desired operating temperature. It is also responsible for monitoring the temperature of the coolant and adjusting the flow rate as necessary to maintain the temperature below the dew point protecting the precious electronics from condensation. DCX CDU’s provides effective separation of the facility circuit and secondary circuit which allows controlled fluid quality and ensures that the cooling fluid in a data centre environment can be kept to a minimum volume, is closely controlled for flow, pressure & temperature and can be accurately maintained for fluid quality.

Some of the key features of a DCX CDU’s include:

- High flow rate: designed to deliver a high flow rate of coolant to ensure that each component in the cooling loop receives an adequate supply of coolant.

- Full remote monitoring: contains temperature, flow and operation sensors that monitor the temperature of the coolant and adjust the flow rate as necessary to maintain a consistent temperature.

- Redundancy: designed with redundant pumps and other components to ensure that the cooling system remains operational in the event of a failure.

- Energy efficiency: CDU’s are designed to be energy-efficient, with features such as variable speed pumps and advanced control systems that help to minimize energy consumption.

Overall, our Coolant Distribution Units play a critical role in the operation of direct liquid cooling systems and hydro systems in data centres, helping to maintain the desired operating temperature and ensure the reliability and efficiency of the cooling system.

FEATURES

-

Enterprise class system & controls with full redundancy

-

Complete loop separation and condensation control

-

From 300kw to 1.2MW per single CDU

-

From 6 to 28 server racks per single CDU

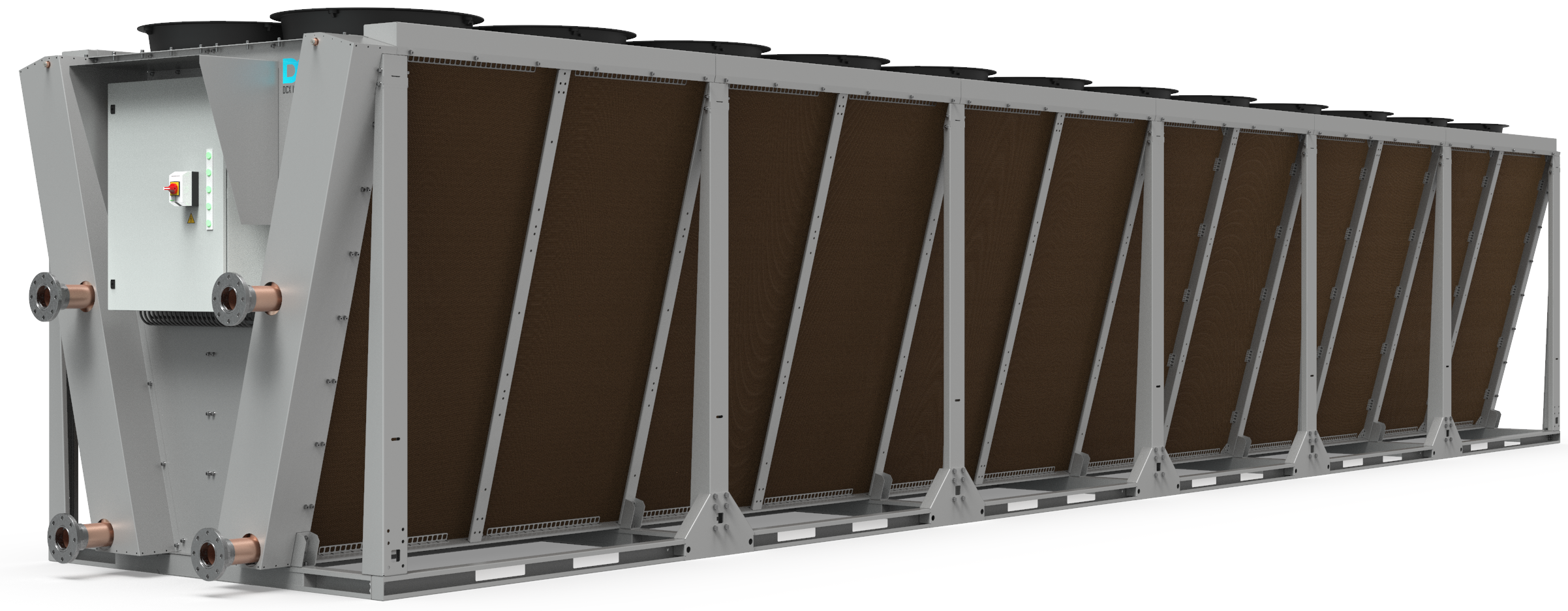

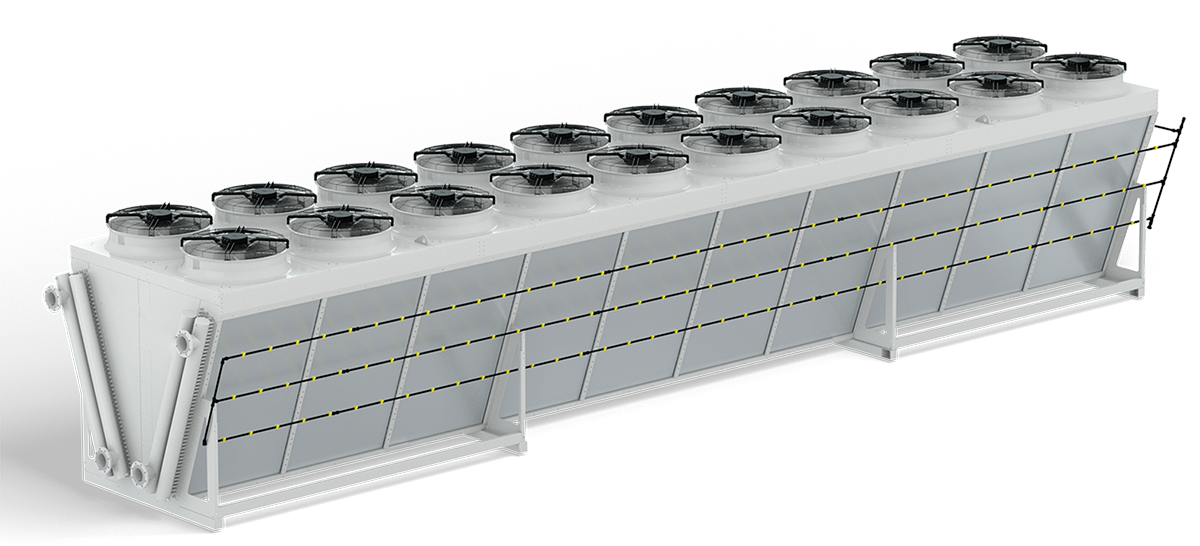

DCX Megawatt Immersion Optimized Dry Coolers

DCX Megawatt Immersion Optimized Dry Coolers designed specifically to solve most demanding heat transfer challenges that crypto mining operators face. Rugged and reliable build combined with minimum footprint – a 20ft container size for 1.2MW and 40ft for over 2MW capable system saves space and allows quick and affordable relocation of the mining operation if required. DCX Megawatt Immersion Optimized Dry Coolers are is built for decades – robust construction, durable coating means it will withstand all weather conditions, including low temperatures, heavy snow, strong rains, wind loads and high humidity. Different from fragile air coolers, equipped only with high quality fans and controllers, DCX Megawatt scale Dry Coolers are compact units to deliver from 1 to 2 MW of heat rejection in 35C / 95F ambient air temperature. We offer 2 platforms produced in EU and also dry coolers produced for us by local US based manufacturer.

OVERVIEW

DCX’s efficient and innovative cooling systems are complemented with a complete and modular portfolio of heat rejection devices – including dry coolers, to address the ability to grow the system flexibly. Dry coolers are specifically designed to solve most demanding heat transfer challenges that crypto mining operators face.

We propose rugged and reliable design and broad portfolio ranging from 15kW to 2MW capable systems. Most importantly our dry coolers are liquid cooling optimized – elevated temperature in our immersion or hydro liquid cooling systems enable crypto mining and datacenter operators to save on heat rejection devices and meet the most demanding operating conditions. The result is reduced footprint, improved capacity & density and lower noise level.

Whatever the requirement, we select a right solution for required capacity and operation altitude, humidity, air & liquid side temperatures. Equipped with premium quality components from trusted suppliers, including reliable fans from Ziehl Abegg & EBM Papst or Schneider Electric and Danfoss electronic controls – to make sure that our systems will operate flawlessly for years.

Our Immersion Optimized range of Dry coolers has been developed specifically to reflect the crypto mining industry requirements and liquid cooling specific temperature range. As opposed to open water towers, close loop cooling systems allow investors to operate without huge environmental and financial cost of evaporated water, boosting both power usage and water usage effectiveness. Dry coolers enable water independent operation virtually any area of the globe.

Based on modular designs of finpacks, our dry coolers are available in a variety of heat exchange capacities: 15kW, 40kW, 120kW, 240kW and megawatt size systems from 1 to 2MW within standard 20ft or 40ft container size. Megawatt line can use spray kit and wet panels for additional cooling efficiency during hottest days of the year. That gives mining operations greatest flexibility in finding the system that suits all requirements. Made in EU, sized to your needs.

Features

-

70% higher heat transfer performance than any other solution

-

Hosts new M56 / M50 and overclocked S19 miners.

-

30-40 x M56 miners per Immersion Rack

-

4MW and 720 miners – most powerful and affordable Immersion Mining Containers

OVERVIEW

1200 kW Immersion Optimized AC Dry Cooler system dedicated for the scale out immersion systems (multiple immersion racks) providing from 1.2 to over 1.6MW of heat rejection for the crypto mining operations. Special build means high efficiency cooling geometry and low pressure drop, enabling lower fan energy use and maintaining moderate noise levels.

DCX Rugged and Immersion Optimized Dry Cooler designed specifically to solve most demanding heat transfer challenges that crypto mining operators face. Rugged and reliable design combined with minimum footprint – a 20ft container size for 1.2MW capable system saves space and allows quick and affordable relocation of the mining operation if required. DC1000S is built for decades – robust construction, durable coating means it will withstand all weather conditions, including low temperatures, heavy snow, strong rains, wind loads and high humidity.

Dry cooler is liquid cooling optimized – elevated temperature in our immersion or hydro liquid cooling systems enable crypto mining and datacenter operators to save on heat rejection devices and meet the most demanding operating conditions. The result is reduced footprint, improved capacity & density and lower noise level.

1.2 MW Immersion Optimized AC Dry Cooler with Industrial, space saving V type platform. It assures over 1924 square meters of heat exchange area with 14 x 65-79 dB(10m), 1000rpm 800mm (10x2100W) AC / or EC fans. The system provides 1200kW of heat transfer in 35*C ambient over 1400kW of heat transfer for average 20-25*C air temperature and up to 1600kW when combined with standard immersion cooling systems. Dry cooler is equipped with energy efficient adaptive fan control.

Optimized for high fluid (60C/140F inlet and /40C/104F) outlet and ambient temperatures (35C / 95F). Cooper (not steel) coils for improved performance. The system offers compact dimensions 7.5 x 2.0 x 2.2m., providing Ziehl Abegg AC or EC adaptive controlled fans for energy efficiency. It fits HC standard container dimensions, which results in its easy transport. Complete system controls based on Schneider Electric Modicon M172 Logic Controller.

Sized for most challenging regions of operation in terms of expected capacity and operation altitude, humidity, air & liquid side temperatures. Equipped with premium quality components from trusted suppliers, including reliable fans from Ziehl Abegg & EBM Papst or Schneider Electric and Danfoss electronic controls – to make sure that our systems will operate flawlessly for years.

Our Immersion Optimized range of Dry coolers has been developed specifically to reflect the crypto mining industry requirements and liquid cooling specific temperature range. As opposed to open water towers, close loop cooling systems allow investors to operate without huge environmental and financial cost of evaporated water, boosting both power usage and water usage effectiveness. Dry coolers enable water independent operation virtually any area of the globe. Made in EU, sized to your needs.

Features

-

1000-1600kW Compact Immersion Optimized, electronically controlled Dry Cooler

-

Maximum performance, minimum footprint with highly efficient geometry

-

Low noise and flexible control options with 7 sound levels

-

Dedicated for High Performance Computing temperature threshold

-

Special rigid frame enables mobility and easy relocation if needed

-

Optional Adiabatic Spray / Panel System

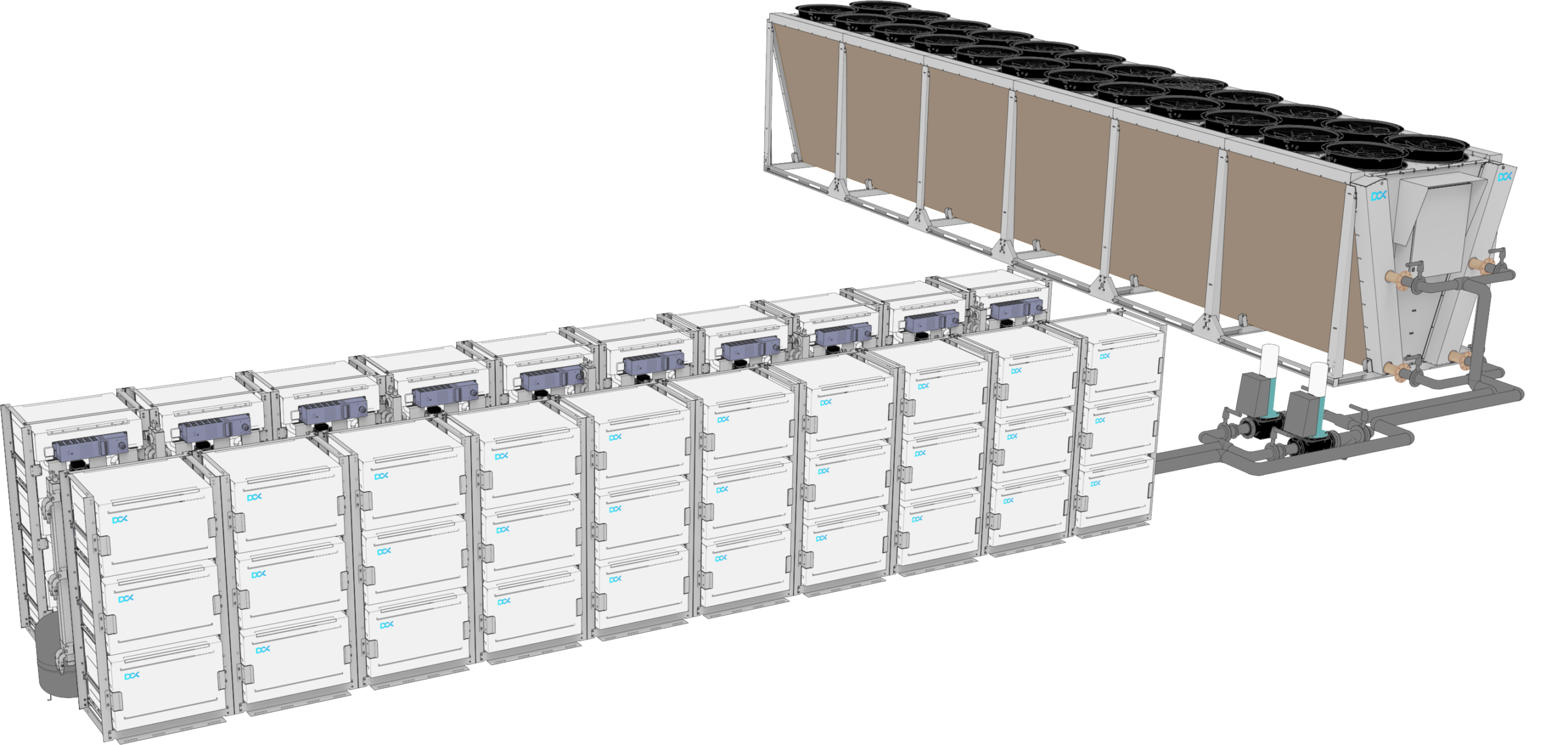

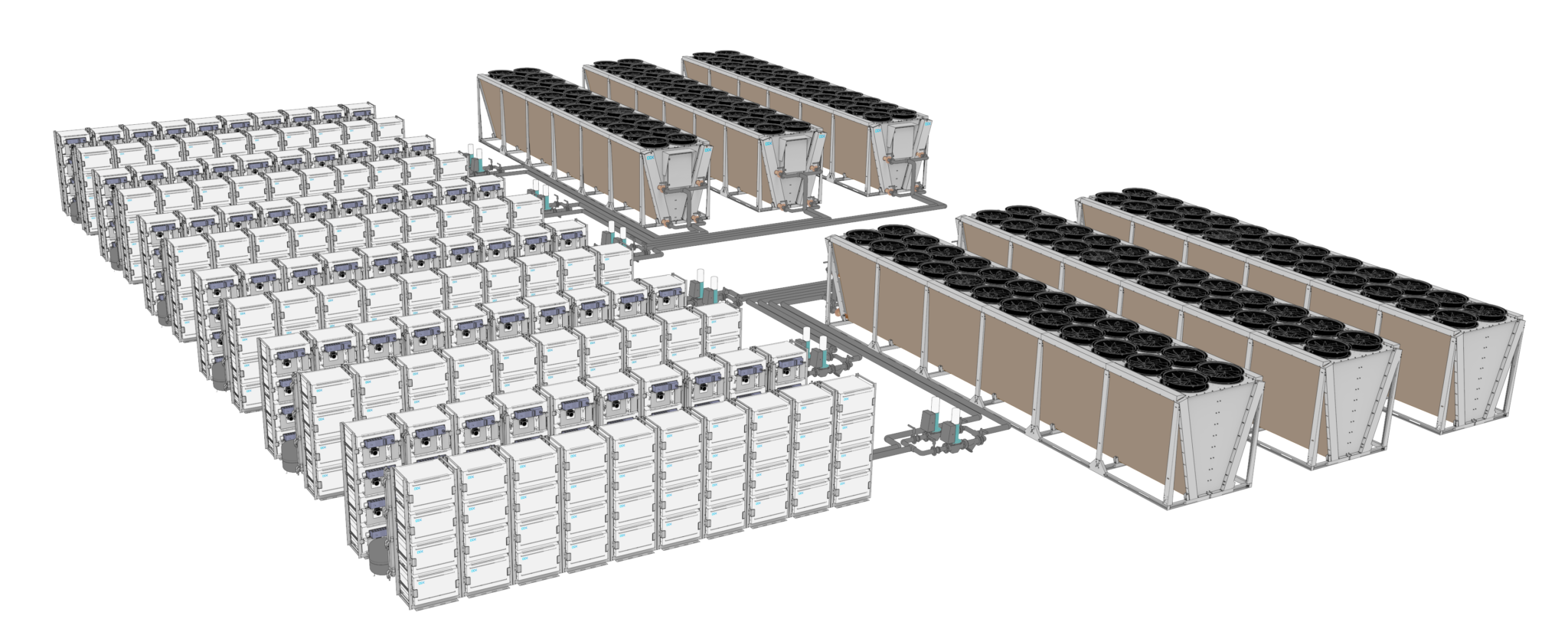

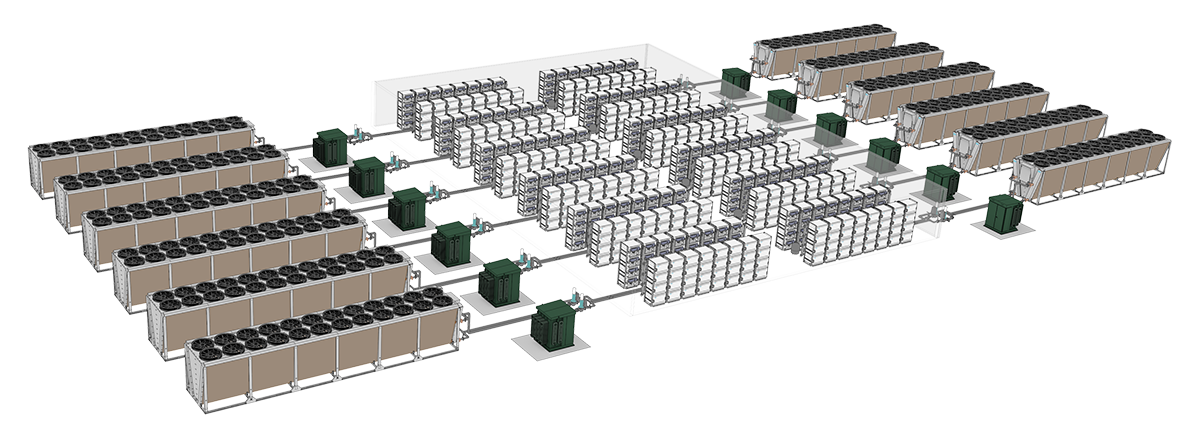

10 MW FACILITY : 2880x Whatsminer M3x or 1920x Bitmain S19j

4 MW installation: 2 rack groups with 2 x 2 MW Immersion Optimized Dry coolers and invidual pumping groups / primary loops.

A complete, modular and flexible immersion system designed for 35C/110F temperatures and future rise in power capacity. Complemented with DCX 2000AC Special Immersion Optimized Dry Coolers. Space-saving rack design with simplified and system-piping and simplified topology. All components are designed to fit standard ISO containers for convenient and affordable transport. That results in easy to maintain, extremely dense enterprise-class data center solution.

- 60 Immersion Racks divided into 3 rack groups (3.36 MW each) connected to 3 individual DCX 2000EC IOD (3.5MW).

- 3x 20 Immersion Rack groups with technical corridors.

- 4 level rack system with 240 Universal Immersion Mining Enclosures for current and future miner models.

- Primary and Secondary Loop Fluid Distribution System based on prefabricated and pre-sized components.

- 240x230L of dielectric Heat Transfer Fluid = 55 000L

- 3x Immersion Optimized Dry Coolers 3.5MW capacity = 10.5 MW total

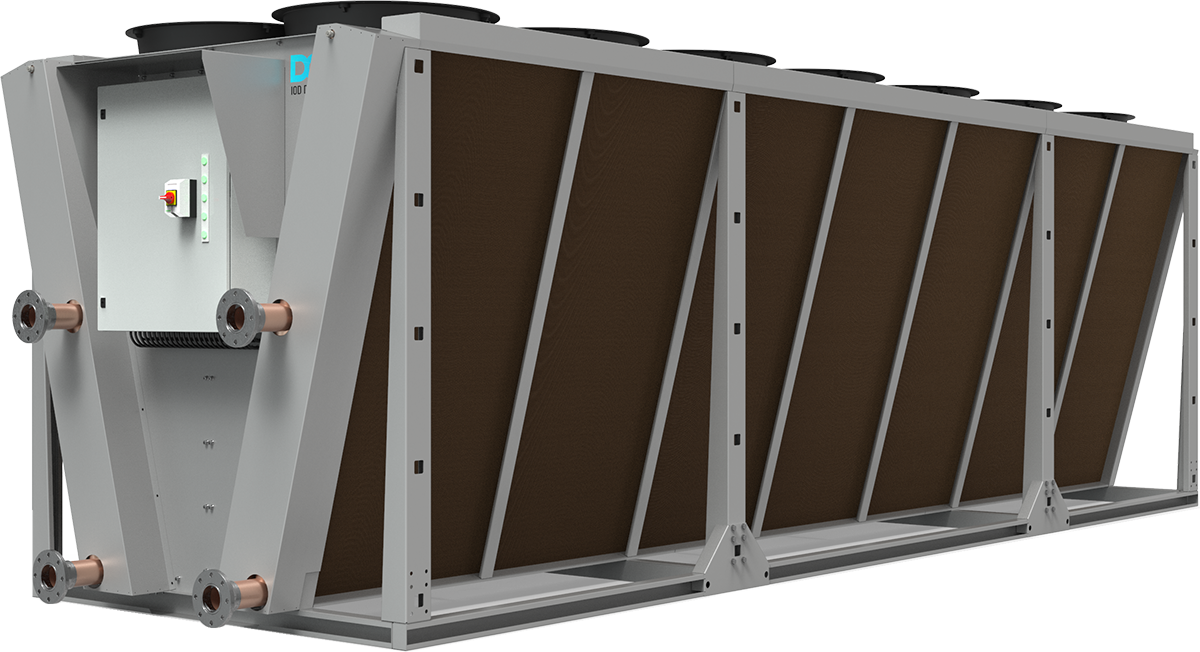

OVERVIEW

2000 kW Immersion Optimized AC Dry Cooler system dedicated for the scale out immersion systems (multiple immersion racks) providing from 2 to 2.8MW of heat rejection for the crypto mining operations. Special build means high efficiency cooling geometry and low pressure drop, enabling lower fan energy use and maintaining moderate noise levels.

DCX Rugged and Immersion Optimized Dry Cooler designed specifically to solve most demanding heat transfer challenges that crypto mining operators face. Rugged and reliable design combined with minimum footprint – a 40ft container size for 2MW capable system saves space and allows quick and affordable relocation of the mining operation if required. DC2000S is built for decades – robust construction, durable coating means it will withstand all weather conditions, including low temperatures, heavy snow, strong rains, wind loads and high humidity.

Dry cooler is liquid cooling optimized – elevated temperature in our immersion or hydro liquid cooling systems enable crypto mining and datacenter operators to save on heat rejection devices and meet the most demanding operating conditions. The result is reduced footprint, improved capacity & density and lower noise level.

The system consists in industrial, V type platform with dimensions of 12.5 x 2.6 x 2.3m. It assures over 4063 square meters of heat exchange area, with 24 x 65-79 dB(10m), 800rpm 800mm (24x 1600W) AC fans. The system provides 1985kW of heat transfer in 35*C ambient and over 2300 kW of heat transfer for average 20-25*C air temperature, up to 2800kW when combined with standard immersion cooling systems. Dry cooler is equipped with energy efficient adaptive fan control.

Optimized for high fluid (60C/140F inlet and /40C/104F) outlet and ambient temperatures (35C / 95F). Cooper (not steel) coils for improved performance. The system offers compact dimensions 12.5m x 2.6m x 2.3m, providing Ziehl Abegg AC or EC adaptive controlled fans for energy efficiency. It fits HC standard container dimensions, which results in its easy transport. Complete system controls based on Schneider Electric Modicon M172 Logic Controller

Sized for most challenging regions of operation in terms of expected capacity and operation altitude, humidity, air & liquid side temperatures. Equipped with premium quality components from trusted suppliers, including reliable fans from Ziehl Abegg & EBM Papst or Schneider Electric and Danfoss electronic controls – to make sure that our systems will operate flawlessly for years.

Our Immersion Optimized range of Dry coolers has been developed specifically to reflect the crypto mining industry requirements and liquid cooling specific temperature range. As opposed to open water towers, close loop cooling systems allow investors to operate without huge environmental and financial cost of evaporated water, boosting both power usage and water usage effectiveness. Dry coolers enable water independent operation virtually any area of the globe. Made in EU, sized to your needs.

Features

-

2000-2800kW Compact Immersion Optimized, electronically controlled Dry Cooler

-

Maximum performance, minimum footprint with highly efficient geometry

-

Low noise and flexible control options with 7 sound levels

-

Dedicated for High Performance Computing temperature threshold

-

Special rigid frame enables mobility and easy relocation if needed

-

Optional Adiabatic Spray / Panel System

10 MW FACILITY : 2880x Whatsminer M3x or 1920x Bitmain S19j

4 MW installation: 2 rack groups with 2 x 2 MW Immersion Optimized Dry coolers and invidual pumping groups / primary loops.

A complete, modular and flexible immersion system designed for 35C/110F temperatures and future rise in power capacity. Complemented with DCX 2000AC Special Immersion Optimized Dry Coolers. Space-saving rack design with simplified and system-piping and simplified topology. All components are designed to fit standard ISO containers for convenient and affordable transport. That results in easy to maintain, extremely dense enterprise-class data center solution.

- 60 Immersion Racks divided into 3 rack groups (3.36 MW each) connected to 3 individual DCX 2000EC IOD (3.5MW).

- 3x 20 Immersion Rack groups with technical corridors.

- 4 level rack system with 240 Universal Immersion Mining Enclosures for current and future miner models.

- Primary and Secondary Loop Fluid Distribution System based on prefabricated and pre-sized components.

- 240x230L of dielectric Heat Transfer Fluid = 55 000L

- 3x Immersion Optimized Dry Coolers 3.5MW capacity = 10.5 MW total

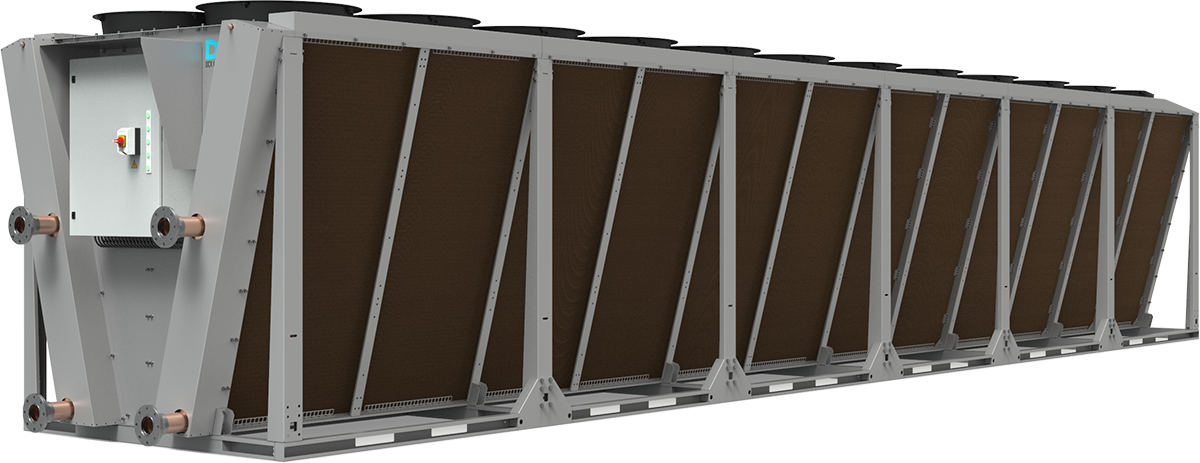

OVERVIEW

2000 kW Immersion Optimized AC Dry Cooler system dedicated for the scale out immersion systems (multiple immersion racks) providing from 2 to 2.8MW of heat rejection for crypto mining operations. Special build means high efficiency cooling geometry and low pressure drop, enabling lower fan energy use and maintaining moderate noise levels.

DCX Rugged and Immersion Optimized Dry Cooler designed specifically to solve most demanding heat transfer challenges that crypto mining operators face. Rugged and reliable design combined with minimum footprint – a 40ft container size for 2MW capable system saves space and allows quick and affordable relocation of the mining operation if required. DC2000S is built for decades – robust construction, durable coating means it will withstand all weather conditions, including low temperatures, heavy snow, strong rains, wind loads and high humidity.

Dry cooler is liquid cooling optimized – elevated temperature in our immersion or hydro liquid cooling systems enable crypto mining and datacenter operators to save on heat rejection devices and meet the most demanding operating conditions. The result is reduced footprint, improved capacity & density and lower noise level.

2.0 MW DCX KLV 2000 SPRAY IOD Immersion Optimized EC Adiabatic Cooler system for the scale out immersion systems (multiple racks). The system consists in industrial, V type platform with dimensions of 12 x 2.9 x 2.2m. It assures over 6304 square meters of heat exchange area, with 20 x 65-79 dB(10m), 930rpm 910mm (20x 1746W / 3.2A) EC fans. The system provides 3.2 kW of heat transfer in 35*C ambient and over 4800 kW of heat transfer for average 20-25*C air temperature. Dry cooler is equipped with energy efficient adaptive electronic fan control. Can be delivered with complementary piping, concentrated corrosion inhibitors / biocides and installation services.

Sized for most challenging regions of operation in terms of expected capacity and operation altitude, humidity, air & liquid side temperatures. Equipped with premium quality components from trusted suppliers, including reliable fans from Ziehl Abegg & EBM Papst or Schneider Electric and Danfoss electronic controls – to make sure that our systems will operate flawlessly for years..

Our Immersion Optimized range of Dry coolers has been developed specifically to reflect the crypto mining industry requirements and liquid cooling specific temperature range. As opposed to open water towers, close loop cooling systems allow investors to operate without huge environmental and financial cost of evaporated water, boosting both power usage and water usage effectiveness. Dry coolers enable water independent operation virtually any area of the globe. Made in EU, sized to your needs.

Features

-

2000-2800kW Compact Immersion Optimized, electronically controlled Dry Cooler

-

Maximum performance, minimum footprint with highly efficient geometry

-

Low noise and flexible control options with 7 sound levels

-

Dedicated for High Performance Computing temperature threshold

-

Special rigid frame enables mobility and easy relocation if needed

-

Optional Adiabatic Spray / Panel System

10 MW FACILITY : 2880x Whatsminer M3x or 1920x Bitmain S19j

4 MW installation: 2 rack groups with 2 x 2 MW Immersion Optimized Dry coolers and invidual pumping groups / primary loops.

A complete, modular and flexible immersion system designed for 35C/110F temperatures and future rise in power capacity. Complemented with DCX 2000AC Special Immersion Optimized Dry Coolers. Space-saving rack design with simplified and system-piping and simplified topology. All components are designed to fit standard ISO containers for convenient and affordable transport. That results in easy to maintain, extremely dense enterprise-class data center solution.

- 60 Immersion Racks divided into 3 rack groups (3.36 MW each) connected to 3 individual DCX 2000EC IOD (3.5MW).

- 3x 20 Immersion Rack groups with technical corridors.

- 4 level rack system with 240 Universal Immersion Mining Enclosures for current and future miner models.

- Primary and Secondary Loop Fluid Distribution System based on prefabricated and pre-sized components.

- 240x230L of dielectric Heat Transfer Fluid = 55 000L

- 3x Immersion Optimized Dry Coolers 3.5MW capacity = 10.5 MW total

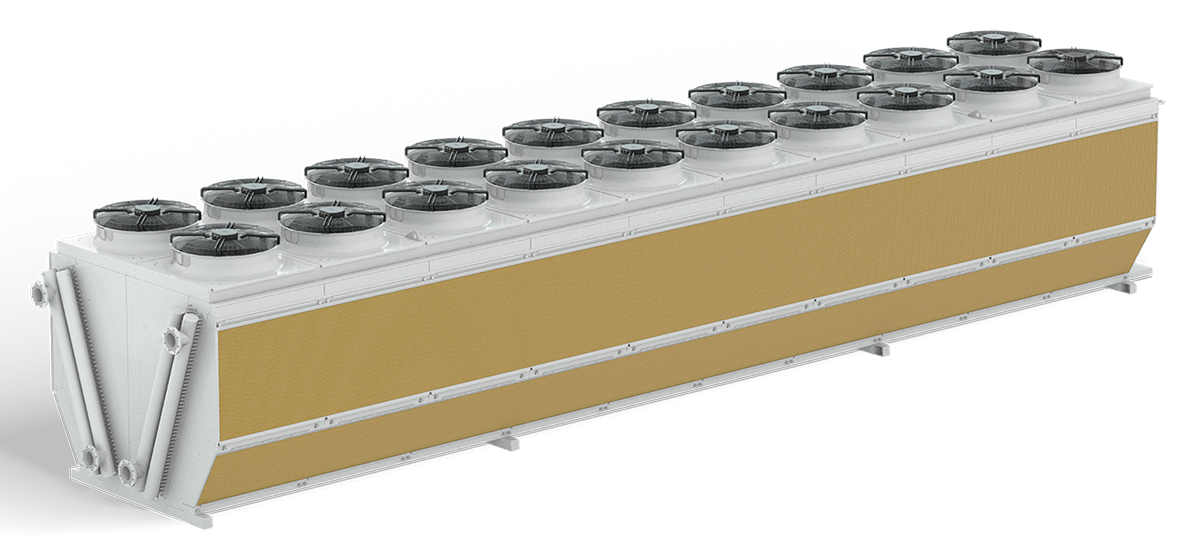

OVERVIEW

3.0 MW DCX KLV 2000 SPRAY IOD Immersion Optimized EC Adiabatic Cooler system for the scale out immersion systems (multiple racks). The system consists in industrial, V type platform with dimensions of 12 x 2.9 x 2.2m. It assures over 6304 square meters of heat exchange area, with 20 x 65-79 dB(10m), 930rpm 910mm (20x 1746W / 3.2A) EC fans. The system provides 3200 kW of heat transfer in 35*C ambient and over 4800 kW of heat transfer for average 20-25*C air temperature. Energy efficient adaptive electronic fan control. Can be delivered with complementary piping, concentrated corrosion inhibitors / biocides and installation services.

3000 kW Immersion Optimized AC Dry Cooler system dedicated for the scale out immersion systems (multiple immersion racks) providing from 2 to 2.8MW of heat rejection for the crypto mining operations. Special build means high efficiency cooling geometry and low pressure drop, enabling lower fan energy use and maintaining moderate noise levels.

DCX Rugged and Immersion Optimized Dry Cooler designed specifically to solve most demanding heat transfer challenges that crypto mining operators face. Rugged and reliable design combined with minimum footprint – a 40ft container size for 2MW capable system saves space and allows quick and affordable relocation of the mining operation if required. DC2000S is built for decades – robust construction, durable coating means it will withstand all weather conditions, including low temperatures, heavy snow, strong rains, wind loads and high humidity.

Dry cooler is liquid cooling optimized – elevated temperature in our immersion or hydro liquid cooling systems enable crypto mining and datacenter operators to save on heat rejection devices and meet the most demanding operating conditions. The result is reduced footprint, improved capacity & density and lower noise level.

Sized for most challenging regions of operation in terms of expected capacity and operation altitude, humidity, air & liquid side temperatures. Equipped with premium quality components from trusted suppliers, including reliable fans from Ziehl Abegg & EBM Papst or Schneider Electric and Danfoss electronic controls – to make sure that our systems will operate flawlessly for years..

Our Immersion Optimized range of Dry coolers has been developed specifically to reflect the crypto mining industry requirements and liquid cooling specific temperature range. As opposed to open water towers, close loop cooling systems allow investors to operate without huge environmental and financial cost of evaporated water, boosting both power usage and water usage effectiveness. Dry coolers enable water independent operation virtually any area of the globe. Made in EU, sized to your needs.

Features

-

3000-4800kW Compact Immersion Optimized, electronically controlled Dry Cooler

-

Maximum performance, minimum footprint with highly efficient geometry

-

Low noise and flexible control options with 7 sound levels

-

Dedicated for High Performance Computing temperature threshold

-

Special rigid frame enables mobility and easy relocation if needed

10 MW FACILITY : 2880x Whatsminer M3x or 1920x Bitmain S19j

4 MW installation: 2 rack groups with 2 x 2 MW Immersion Optimized Dry coolers and invidual pumping groups / primary loops.

A complete, modular and flexible immersion system designed for 35C/110F temperatures and future rise in power capacity. Complemented with DCX 2000AC Special Immersion Optimized Dry Coolers. Space-saving rack design with simplified and system-piping and simplified topology. All components are designed to fit standard ISO containers for convenient and affordable transport. That results in easy to maintain, extremely dense enterprise-class data center solution.

- 60 Immersion Racks divided into 3 rack groups (3.36 MW each) connected to 3 individual DCX 2000EC IOD (3.5MW).

- 3x 20 Immersion Rack groups with technical corridors.

- 4 level rack system with 240 Universal Immersion Mining Enclosures for current and future miner models.

- Primary and Secondary Loop Fluid Distribution System based on prefabricated and pre-sized components.

- 240x230L of dielectric Heat Transfer Fluid = 55 000L

- 3x Immersion Optimized Dry Coolers 3.5MW capacity = 10.5 MW total

Quick intro

Unboxing of the Immersion Enclosure package and quick intro to the system components.

What you get – bundle

Enclosure with a 40kW dry cooler. We have a new ICP40 now, but you see what you get in the bundle package.

Installation & Startup

You bought the package – now what? Quick installation guide for effective commissioning of this smart immersion cooling system.

OVERVIEW

DCX’s efficient and innovative cooling systems are complemented with a complete and modular portfolio of heat rejection devices – including dry coolers, to address the ability to grow the system flexibly. Dry coolers are specifically designed to solve most demanding heat transfer challenges that crypto mining operators face.

We propose rugged and reliable design and broad portfolio ranging from 15kW to 2MW capable systems. Most importantly our dry coolers are liquid cooling optimized – elevated temperature in our immersion or hydro liquid cooling systems enable crypto mining and datacenter operators to save on heat rejection devices and meet the most demanding operating conditions. The result is reduced footprint, improved capacity & density and lower noise level.

Whatever the requirement, we select a right solution for required capacity and operation altitude, humidity, air & liquid side temperatures. Equipped with premium quality components from trusted suppliers, including reliable fans from Ziehl Abegg & EBM Papst or Schneider Electric and Danfoss electronic controls – to make sure that our systems will operate flawlessly for years.

Our Immersion Optimized range of Dry coolers has been developed specifically to reflect the crypto mining industry requirements and liquid cooling specific temperature range. As opposed to open water towers, close loop cooling systems allow investors to operate without huge environmental and financial cost of evaporated water, boosting both power usage and water usage effectiveness. Dry coolers enable water independent operation virtually any area of the globe.

Based on modular designs of finpacks, our dry coolers are available in a variety of heat exchange capacities: 15kW, 40kW, 120kW, 240kW and megawatt size systems from 1 to 2MW within standard 20ft or 40ft container size. Megawatt line can use spray kit and wet panels for additional cooling efficiency during hottest days of the year. That gives mining operations greatest flexibility in finding the system that suits all requirements. Made in EU, sized to your needs.

FEATURES

-

70% higher heat transfer performance than any other solution

-

Hosts new M56 / M50 and overclocked S19 miners.

-

30-40 x M56 miners per Immersion Rack

-

4MW and 720 miners – most powerful and affordable Immersion Mining Containers

OVERVIEW

Two years ago, DCX pioneered introducing scalable and modular Immersion Enclosure & Immersion Rack System, delivered to thousands of customers. With new overclocking firmware and 6kW PSU’s we had to improve the system to make it the best option for high performance mining. Upgraded PRO9 Immersion Mining Enclosure has been engineered to provide effective heat transfer for overclocked miners. With rated cooling capacity of up to 48kW it will support S19 with optional 6kW PSU or dense 12 x Whatsminer configs.

In opposite to long tanks with multiple miners, DCX Immersion Enclosure saves space, allows starting with small investment of single enclosure system, and allows mining at scale with multiple immersion tanks connected to primary cooling loop. Miner specific and replaceable internal components provide balanced flow and saturation of each device. Bigger plate heat exchanger, fittings, pump will support your operation during the hot summer days. Proven 48kw heat transfer performance from each enclosure, and over 140kW (3 level rack) in DCX immersion mining rack. In the result of smart and efficient design ΔT of the system reaches from 15C to even 20C instead of 10C which is a generic in long tanks). The system has been designed for heat reuse applications – elevated temperature set point (40C/104F inlet & 60C / 140F outlet) enables additional cost savings when purchasing heat rejection devices (dry coolers) and allows for sustainable and effective heat utilization for facility heating or different industrial applications. Higher set point temperatures also allow to plan efficient cooling of cryptomining operation in the hottest areas of the globe, including the Middle East ambient temperatures.

We deliver the immersion tank with additional sensor which remotely monitors the temperature. We chose the heigh of the tank so customers can fit longer miners (K3 and similar) and manage the ethernet and power cables. Stackable in PRO9 Immersion Rack System, DCX PRO9 Immersion Enclosure can be installed in facility or high-density containers.

FEATURES

-

70% higher heat transfer performance than any other solution

-

Hosts new M56 / M50 and overclocked S19 miners.

-

30-40 x M56 miners per Immersion Rack

-

4MW and 720 miners – most powerful and affordable Immersion Mining Containers

PRO 9 IMMERSION MINING ENCLOSURE

The most popular immersion cooling system in the world, but upgraded with 40% larger heat exchanger and 1.5x stronger pump than its predecessor. Dedicated for overclocked cryptomining delivers 48kW heat transfer from single enclosure at 40C/104F inlet & 60C/140F outlet. Dedicated for all popular miners, hosting 8 x Antminer S19 family or similar and 12 x M30 MicroBT Whatsminers. PRO9 Immersion Mining Enclosure is equipped with miner specific flow plates and grids to provide balanced flow and saturation for all miners. System can be stacked in Immersion Rack System for megawatt sized installations.

Technical Specification

Features

-

70% higher heat transfer performance than any other solution

-

Hosts new M56 / M50 and overclocked S19 miners.

-

30-40 x M56 miners per Immersion Rack

-

4MW and 720 miners – most powerful and affordable Immersion Mining Containers

PRO 9 IMMERSION MINING ENCLOSURE