What are the product specifications/dimensions of your enclosures/racks/dry coolers?

You can find all the necessary information regarding weights, dimensions and other product specifications on our website cryptocooling.eu (“Product Specifications” tab). All you need to do is to scroll the page down till you find the product of your interest and search for specs in a description or among the horizontal tabs above it. You can also navigate the website using the upper panel.

How much space is needed for immersion system?

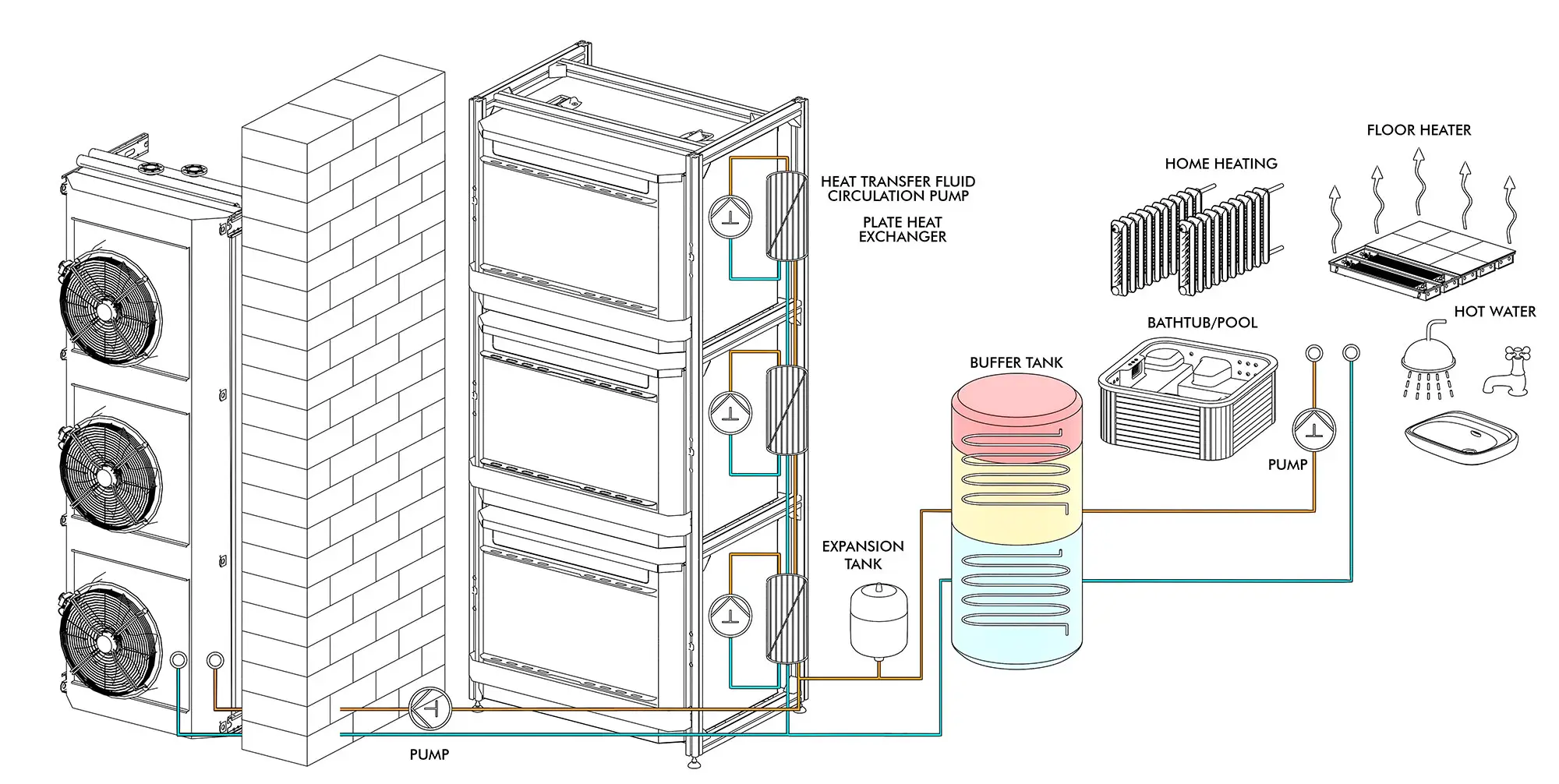

Our immersion cooling systems are quite compact. Every system consists of 2 major units – an immersion tank (or tanks placed vertically one upon another in a rack) and, optionally, a dry cooler. An immersion tank (enclosure) has a 1 sq meter footprint, roughly. Dimensions of dry cooling units are rather various, depending on their model and heat rejection capacity. You can find all the necessary information regarding weights, dimensions and other product specifications on our website cryptocooling.eu (“Product Specifications” tab).

Where can I install immersion system? Can I install dry cooler inside the building?

It’s essential to install a dry cooler outside of your facility. By no means can it be placed inside. Please note that every dry cooler sucks air from the rear and blows out through the front side, so remember to preserve a gap of at least 30 cm between the back the device and a wall it’s hanged on or the ground (in case of a 120kW dry cooler, if you decide to install it horizontally).

How much power does the enclosure system/rack consume?

Overall power consumption of both a single enclosure and a rack system is basically a summary of several components that require electricity for sustainable work of the system that they are a part of. Those elements are pumps and fans. Each part is described in “product specs” section on the website. Roughly, total power consumption is 1kW for a single enclosure system and 3kW for a rack.

I'm located in USA, i have 110V / 240V split phase.

In order to run our systems you may need a voltage converter that will convert your power to desired voltage (please find examples here: https://www.amazon.com/gp/product/B002IU36J2) or here: https://www.amazon.com/Yinleader-Voltage-Transformer-Converter-120Volt/dp/B07PPZLX5K/?th=1 /

You need conversion to EU/Asia 220-240 VAC with at least double capacity than the connected component power for continuous use. So for the enclosure you’re going to need a 2.5-3kW voltage converter. One of those devices is all we need for single enclosure with 40kW ICP40 dry cooler https://www.amazon.com/Rockstone-3000-Watt-Transformer-Converter/dp/B00CLYMMCC/

So, just a voltage converter from 110V to 220V. All we need is single phase 220-240V.

What material are your enclosures made of?

Our immersion tanks and fittings components are all made of steel. So cooling systems that we provide don’t require special grounding procedures, as in case with plastic. Also, they will never melt like plastic exposed to high temperatures, and they won’t crack due to the influence of hot oil, sudden shifts of temperature, etc. As a matter of fact, our immersion cooling systems are designed as a one-time investment that should last for a long time and be able to perform with future miner types. You can mix different miners in one enclosure without any problem.

How many miners can I immerse in your enclosure?

We offer steel immersion tanks that can be used for both ASIC miners and GPUs. You can find all the necessary information regarding weights, dimensions and other product specifications on our website cryptocooling.eu (“Product Specifications” tab). A single enclosure system is a perfect fit for 8 units of S19j (L7, Avalons 1246, Goldshells or any other machines of similar size) or 12 units of Whatsminers or 16 units of S9.

Can I use different miner models? Can I mix miner models inside of the enclosure?

It’s possible to mix different models of ASIC miners inside one immersion tank. However, it’s strongly recommended to keep the inner space of the enclosure as occupied as possible. The perfect configuration is 8 of S19 Antminers, because it leaves literally no gaps for the fluid to bypass them. You can find all the necessary information regarding weights, dimensions and other product specifications on our website cryptocooling.eu (“Product Specifications” tab). Again, please note that it’s important to sustain pressure inside the inner space of the tank. Keep it as occupied as possible, so that fluid doesn’t flow to empty space, where pressure is lower. We recommend filling gaps with empty fluid canisters.

Can I use your Immersion Enclosures for GPU immersion?

There are various kinds of GPUs, and the difference in size between them can be pretty much significant. Let’s presume a scenario with 30XX models, which happen to be the largest one on the market in terms of size. Depending on how you intend to immerse them, you can fit from 32 to 60 of them in a single enclosure. If you decide to immerse them being connected directly to mainboards, you’ll be able to fit the minimum (4 rows, 8 cards in each). However, if you connect them with risers, you’ll gain more space for immersion (up to 15 cards in each row). You can find all the necessary information regarding weights, dimensions and other product specifications on our website cryptocooling.eu (“Product Specifications” tab). Again, please note that it’s important to sustain pressure inside the inner space of the tank. Keep it as occupied as possible, so that fluid doesn’t flow to empty space, where pressure is lower. We recommend filling gaps with empty fluid canisters. Mixing ASIC miners with GPUs would be a bad choice though – there would be no way to avoid the gaps.

Does Immersion Cooling eliminate noise from the miners?

This is by far the main purpose of immersion cooling systems. There’s no secret that ASIC miners are extremely loud, especially when there are dozens and hundreds of them. It’s not only irritating for your neighbors, but also quite dangerous for your hearing. When immersed, miners are maximally quiet due to the lack of fans that actually produce the exasperating noise. The only sound you’ll hear is a slight buzz of a working pump (~25dB) and a dry cooler outside of your facility. Dry coolers have special fan speed controllers that adapt power of the fans to temperature in the loop. Most of the time it’s barely hearable, but on the hottest summer days when they work at max fan speed the level of noise is only ~75dB.

I plan to grow my system from single enclosure to multiple racks. Is it possible?

There’s a possibility to upgrade a single enclosure system to a full rack. Every enclosure is a building block for bigger solutions – we simply stack them up like LEGO blocks. If you consider future expansion of your mining facility, a rack could be a good start for a bigger farm. You should be aware of one thing though – a rack system comes with a 120kW dry cooler, which is a thrice more powerful unit, that comes with a single enclosure system. Such an upgrade will leave you with a spare ICP40, but it won’t be difficult to resell it to someone else though. The small dry cooler is always in great demand on the market and we can even help you with reselling it to some local client who’s eager to buy it asap.

I have 100 x S19 miners, what are my options?

There are different types of miners and their sizes (the most important aspect when it comes to estimating an immersion cooling scenario) can vary significantly. The most popular model is S19j Pro though – most of our clients operate those. 4 rack systems can fit 96 of S19 Antminers and it’s up to a customer to choose a heat rejection scenario. Heat reuse is strongly recommended, but with a lack of an effective heat reuse scenario we offer several models of dry coolers that can successfully deal with system’s overheating: 120kW units (one unit for each rack, which makes total of 4) or 240kW ones (2 dry coolers for 4 racks).

I plan 1MW system or more. What are my optons?

We started 2-3 years ago from a small scale offering only single enclosure bundles, but since that time we’ve fulfilled a few multi-megawatt scale contracts. Our Immersion Mining Rack systems are the most compact, most affordable and most space saving solution for several-megawatt scale out installations. In this particular case, 1-1.1MW system with mildly overclocked miners means 10 Immersion Mining Racks with 3 Immersion Mining Enclosures in each rack system. Such an installation can be very dense and will require just 8×3 meters / 260 sq feet of space for a dry cooler outside of your facility, and 5 x 5 m (25 sq meters / 270 sq feet) for immersion rack group or 10×3 meters row. Please contact us and we will arrange a 1h teleconference in order to walk you through the technology, process and options we have to offer from 1MW to 50-100-200MW installations.

Can I reuse heat from my miners?

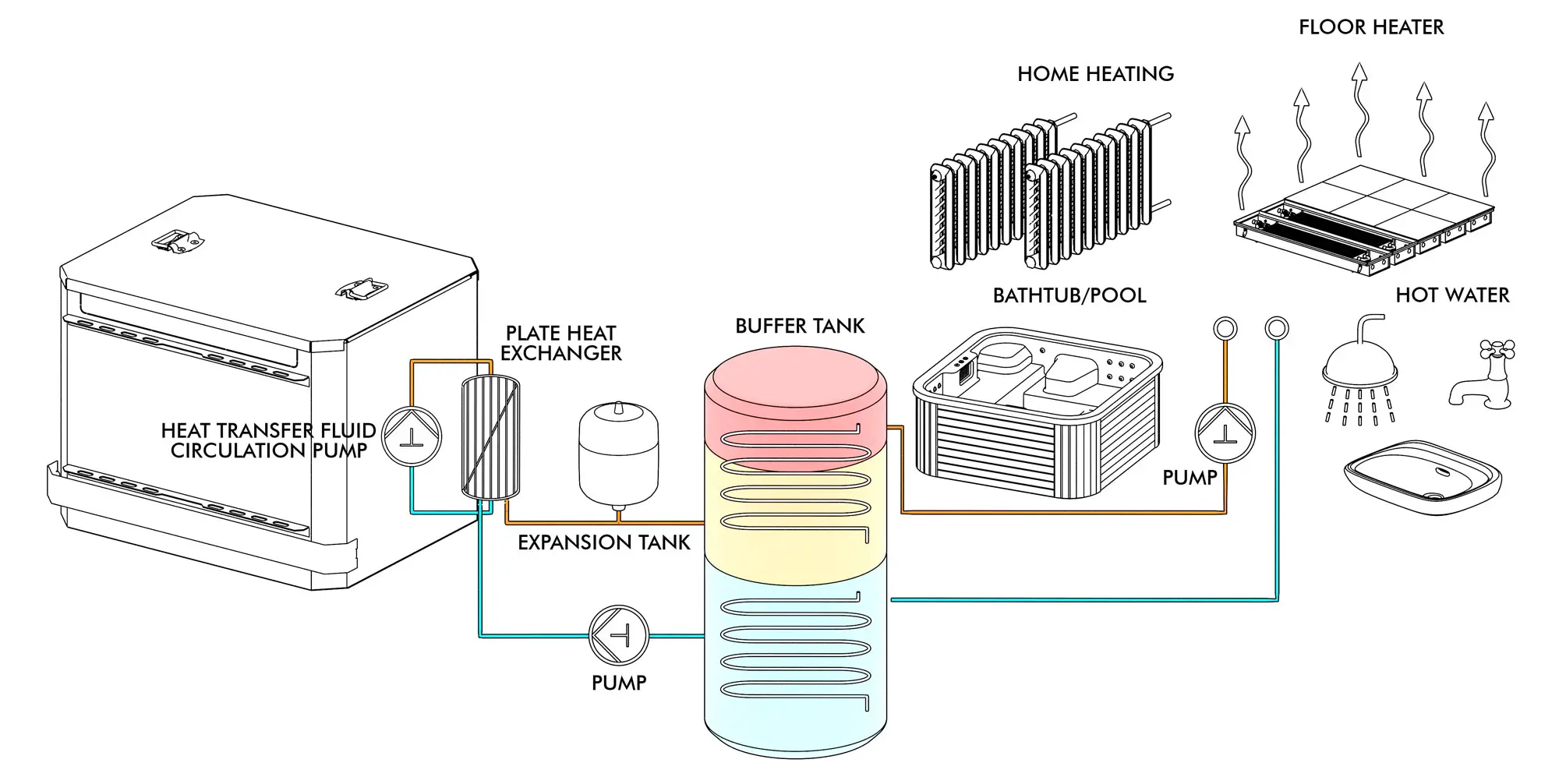

Of course, heat reuse is one of the reasons why we provide dual loop systems. In such systems dielectric engineered fluid Thermasafe R circulates inside of the enclosure and rejects heat through an integrated heat exchanger. Customers can connect cooling systems to our Immersion Optimized Dry coolers via the heat exchanger, or they can connect the enclosure to a home / facility water circulation loop, if it’s possible. This way you can reuse the heat to warm your own house up. You can use enclosure systems to heat up wall mounted radiators, floor heating installations, entire swimming pools or hot tubs. The only thing you have to consider is that you need to connect our enclosure to the clean heating water or to a pool heat exchanger as pool water is treated with chlorine, salt or sodium chloride (NaCl) additives and will corrode our brazed plate heat exchangers. DCX Immersion Rack groups and our primary loop systems are also designed to reuse heat at industrial, large scale. And there are different, ingenious ways bitcoin miners recycle heat from ASICs:

✅Water heating – with return temperature in our enclosure elevated to 60C / 140F its enough for home or facility hot water circuit for an all-day purpose. The same concerns industrial scale or any production process. You will get 60-65C hot water supply 24/7 365 days a year.

✅ Greenhouse conditioning – to preserve certain climatic and environmental conditions in order to grow vegetables, flowers, and fruits. Repurposing ASIC miners’ heat to facilitate the climatic conditions for vegetation growth is particularly helpful in cold weather locations with fewer sunny days, like northern countries such as Canada, Finland, or Sweden. There are large applications with greenhouse heat reuse from typical food / flower farms but also for awesome cannabis farms in USA where law allows cannabis production (with tegrity).

✅ Food and drink production – food production systems like fish — aquaculture, algae, hydroponics, and insect farming all involve supplementing heat and can be combined with a Bitcoin mining operation to provide it. Another significant application for ASIC miners’ heat for the food industry is preservation as fruits, vegetables and meats may require drying and dehydration to prevent spoilage. Perhaps the most creative way for ASICs’ heat for industrial purposes is whisky production. Distilling alcohol requires high temperatures, and distilleries often have dedicated heating systems.

✅ Wood drying – whether to use it as construction material or as fuel, wood needs to be dry first. This can be a long process, so lumber yards often rely on artificial drying methods. Artificial or “oven” drying consists of storing the wood in thermally insulated chambers — called kilns. Once there, it is exposed to heat using natural gas or electricity through steam-heated heat exchangers. As you can imagine, generating heat through this process involves considerable costs due to the additional energy required. ASIC miners can provide the necessary heat for wood drying while helping mitigate those losses through Bitcoin earnings. Instead of using natural gas, ASICs’ heat is transferred into the kilns through corrugated air pipes, raising the temperature and drying the wood for its industrial purpose.

✅ Water desalination – this energy intensive process requires distillation so that provides excellent opportunity to supply base heat from the bitcoin mining operation.

Does immersion cooling produce a lot of AMBIENT heat? Is it Dry heat or Wet Heat?

Our immersion cooling systems are designed not only to remove heat from the miners. Beside quite effective heat rejection our solutions are good at removing noise and protecting devices from vibration, overheating, dust, corrosion, humidity etc. In order to have the most compact heat rejection installation that we can offer (a small dry cooler with 40kW of heat rejection capacity), we run miners in high temperatures. During a winter / moderate temperature season we should get up to 30C on inlet and 50C on outlet. During hot seasons to 40C and 60C respectively, which makes a delta of 20C on return from the enclosure. It means the enclosure will be hot during summer, which is perfectly fine for the hardware. However, a fully occupied enclosure (8 miners with 30-40kW of power) radiates up to 900W of dry heat outwards, protecting the miners and fluid from humidity. It’s great for different heat reuse scenarios, but if you want to save all heat for other purposes, we suggest using some form of isolation of the enclosure – blanket / rug to wrap the tank up. Also having proper ventilation is strongly recommended.

During sumer time I will have 40C / 104F outside - will your system work?

Initially, dry coolers are not designed to work in extremely hot climates, such as tropics. The principle of dry coolers’ work is the use of surrounding air, which is not that efficient when the ambient temperature is 45C or even higher. In this case performance of the system will be degraded, but still it would be able to support the work of S19 ASIC miners, even overclocked ones (provided the dry cooler is installed in a shady place, preferably on the northern side of a facility).

I live in Middle East, we have really high ambient temperature - over 50C / 120F - will it work?

Our dry coolers are designed for ambient (outside) temperatures of up to 35C / 95F. So it means that during hot summer days they will only supply our immersion enclosures with hot water (up to 40C / 104F). In this case the outlet temperature reaches 60C / 140F, and on chips we warm up to approx 75C. If dry coolers have to operate in higher ambient temperatures, performance will be significantly degraded. Additionally, they will use surrounding air, which will be as hot as ambient temperature outside of your facility. Provided the outside temperature is higher than expected, it can result in miners overheating. For middle east temperatures we suggest connecting the cooling system to a facility water or a chiller station. In some locations customers can connect it to a central building chiller, which usually provides cold water to local air conditioning units. Please remember that we can use water of up to 40C, so anything colder than that is great for cooling your miners – you’ll be able to reuse wastewater then.

I have dusty / corrosive environment? Can I use immersion coling system?

Needless to say, immersion itself saves your devices from almost all the possible contacts with damaging environmental factors. Moreover, every enclosure has a metal upper lid that closes the tank from above, granting it extra protection. It helps to save the precious dielectric fluid from any kind of contamination, including dust, corrosion, tin whiskers, germs etc. This allows you to run the cooling system literally everywhere without implementation of additional means of protection.

How much can I overclock S19 using your immersion cooling system?

Our Immersion Enclosures are sized for 40kW of heat rejection (in single enclosure or single rack configurations). But in scale out system solutions that we also design, we can get as much as 46kW heat transfer from a single enclosure. Thus, in case of overclocked S19 Antminers, most operators can overclock these machines from nominal 3250W to 3600W up to 4600W. Scale out systems’ users can push that limit even up to 5750W per miner. Of course, we assume those numbers provided we work in a pretty hot climate, hot summer days, and also that we supply our immersion enclosures with hot 40C / 104F water. According to this scenario, the outlet temperature reaches 60C / 140F, and we get approx 75C on chips. If we get colder water or inlets, then the overclocking threshold will be even higher.

How profitable is your cooling system?

Immersion cooling is not the cheapest investment compared to air cooling. So you need to invest more in the initial phase by spending more on fluids and enclosures – such an enterprise is definitely more expensive than typical warehouse shelves for air-cooled miners. On the opposite, you have a much better density (less space is occupied), no need to install any fans, filters or additional cooling systems. Of course, the bigger the system, the more significant savings can be achieved. With a home-based installation, there’s nothing to be worried about ROI or TCO, but with large installations, we are speaking about millions’ incomes. The idea for immersion cooling is:

- much higher hashing rate thanks to overclocking (which is not possible with air cooling) and faster ROI

- much longer lifetime for miners and lower TCO

- no dust, no noise, no overheating, no chips or dashboards burning

- lower maintenance cost

- no filters to be exchanged, no problems with fire, bacterias, fungus, and other “stuff”

- zero cost of the additional installations service and maintenance – fewer repairs and maintenance actions, fewer labor costs

- lower OPEX, better ROI – much better MTBF – better ROI

- OVERCLOCKING

- very high density of miners, significant space savings

- possibility of selling miners after 2-3 years in the fluid “as new” – much better ROI

So it’s not only about purchasing a liquid cooling system itself, but also about perspectives that unravel in time. Our single enclosure system requires just ~1kW of electric power to reject 40kW of heat. Our full rack system requires just about 3kW to cool down up to 120kW. So as you see, it’s very cost-effective, and such a cost may be neglected in the process of making calculations of ROI as it represents just a small % of a total cost. When it comes to overclocking, immersion cooling makes it possible to boost an S19 from default 110Th at 3250W per miner up to 140-142Th at 4600W. In extreme overclocking scenarios immersion systems can push efficiency from base 110Th to 180-190th to over 7000W per miner.

Is there any warranty on your products?

Our products are a one time purchase, which means it will serve you for a really long time (and most probably outlive you). They are made of steel, not plastic, so don’t expect them to crumble after several years of usage. We provide a 180 days warranty for fans and pumps. In addition to that, we can also arrive at your location, install the system and teach you to maintain it from then on (if you have a bigger scale-out project), or provide you with online support (if you’ve got a small mining project).

Do you provide support for customers? What if I will have problem?

Of course, we support customers directly. All information related to the installation of an Immersion Enclosure or an Immersion Rack may be found on our website (“Installation Manuals” section): https://cryptocooling.eu/manuals/ .

Also, quite detailed information about installation of the system can be found on our youtube channel: https://www.youtube.com/c/DCXLiquidImmersionCooling/videos

You may also find some answers to common questions in the https://cryptocooling.eu/faq-2/ section.

Please go through these materials and if you find some issue during installation, we are available to support you directly via communication channels listed below:

Email: support@dcx.eu

Whatsapp: DCX SUPPORT / +48 783 925 978

QR Code: https://wa.me/message/GSGUDTNFZUBFF1

Telegram: https:/t.me/DCXHelp @DCXHelp

What are the concerns or disadvantages of immersion cooling?

With so many benefits it’s hard to say whether there are any significant disadvantages at all. However: 1. Some may perceive an immersion operation as a “more messy” method of cooling as we deal with dielectric hydrocarbon based engineered fluids which happen to be essentially specialized oils. 2. Another concern is that you need to prepare miners for immersion and once you immerse them, you need to treat them with special solvent (which we provide) to clean them again if you would ever want to sell them as air cooled. 3. Finally, you need to educate yourselves in maintenance of the dry cooler, immersion tank, cable management of the immersion enclosure etc.

Can immersion cooling reduce electricity costs?

Immersion cooling doesn’t reduce power draw per se. Of course, in order to immerse your devices you need to remove fans from the miners, but these are just a few watts per fan. There’s no magic here, as we’re not using a magic fluid. On the opposite – you may expect higher power drawn when you overclock your miners (which is nearly not possible to achieve with air cooling). On the other hand, immersion cooling saves you from running the following devices:

Large fans that pushes air to the facility (100% reduction)

HVAC system to cool the air (100% reduction)

You don’t need filters (100% reduction)

You will limit the maintenance of the whole farm to a minimum level (xx% reduction)

Calculations will be different for various customers from different regions. A small example from an owner of 500 GPUs in Arizona: he claims he’s spending just 1600$ monthly on air purification, and he has to do a constant and neverending GPU cleaning routine – day by day. With the immersion cooling, all his problems and costs related to that will be solved. And he can pack all his miners in ~3 racks, that will occupy 3sq meters and not 30. So, savings are coming from all sides.

What is immersion cooling - how it works?

Immersion cooling is a process of cooling electronic components (ASIC miners, GPUs, CPUs, servers, etc) by submerging them in specially engineered fluids. It is a non-conductive, dielectric fluid that looks like water, but does not lead to short circuit of your electronics. The fluid has great heat absorption capacity which is 1500x better than heat transfer capacity of air.

Miners that are immersed use no fans (with span spoofers or with custom firmware) so you don’t need any air handling, additional fans in the facility or noise protection. So the operation can be done both in commercial and residential areas. Then you may connect the whole system to water loop or a drycooler that we also deliver.

By circulating the fluid through hardware devices, heat is removed and transported away to an external heat rejection device – a dry cooler, a heat exchanger or any water loop. It also allows you to implement heat reuse applications for home, office, warehouse, swimming pool, greenhouse heating etc.

What are the main benefits of liquid cooling over air cooling?

Liquid cooling with a dielectric (non-conductive) fluid offers a variety of benefits over traditional air cooling. Let’s list just a few of them, that influence your mining operations.

- Higher level of cooling efficiency – The liquid transfers heat more effectively because of its high thermal conductivity. You can assume that liquid is ~1500 times better than air. It means that you can use 1 liter of the fluid or 1500 liters of air to achieve the same cooling effect. That’s why fans of your miner generate so much noise. They must push a huge amount of air through the hashing boards, while the fluid can just flow slowly.

- Brings overclocking potential – Overclocking is the process of setting microchips at a higher frequency. However, this process can damage them if you’re not careful. In fact, it increases the heat generated by your system. Liquid cooling keeps your overclocked hardware cooler, so you won’t crash your computer or damage your hardware because of overheating. At the same time, you can mine more coins, as hash rate of your miner can be raised significantly (for example with S17 you can overclock your miner by ~40% for sure). So, you can assume a much faster ROI than the one with air cooling.

- Silent operations – Liquid cooling reduces the need of using fans to zero. A typical ASIC miner generates ~80dB of noise. The same unit immersed in the fluid generates ~0dB! This is the biggest problem for those who want to mine at home or office.

- Most liquid-cooled systems need to dissipate heat with the use of a dry cooler, that should be placed outside, and its fans generate ~60dB which is comparable to noise of a vacuum cleaner.

- No dust – As all miners are under the surface of the fluid, the main problem – dust, as well as all failures and maintenance costs related to it – is solved. You don’t need additional filters and fans any more. Also, you may forget about work related to its replacement. Simply, no maintenance is needed.

- Fewer repairs and servicing actions – As all miners work in stable conditions, separated from the environment (dust, humidity, heat), you can run your mining operations without unnecessary breaks and in distant locations with limited access to service.

- Stable temperatures over time – Working temperature of the fluid in the loop is stable. It’s good for you miners. There will be no hot-spots, no overheating, no damage. It allows your miners to work for a much longer period of time without failures and protects your investment. You can install it in hot or freezing ambient temperature, where free air cooling will not work (because of dust or condensation of humidity and corrosion).

- Liquid cooling saves space – When it comes to real estate, liquid cooling simply rocks. You can squeeze much more miners into immersion enclosures than into a typical free air cooling installation. It can be 4 to 5 times more miners in the same footprint. Just to say – our rack system allows you to place 24 big miners like S19 into the floor space of 1 square meter.

- High density – You can really squeeze your miners tight. No separation between miners is needed, unlike from what you may see in case of air cooling systems. You can put 3 – 5 times more miners in one container based on immersion cooling than in a typical air-cooled one. It saves lots of CAPEX when building a farm, and OPEX during operations.

- Good for hot climate and polluted areas – High ambient temperatures were a stopper for mining operations, as cooling miners with HVAC systems are very costly. Liquid cooling solves this problem. As the water system works on an ongoing basis, those who work in naturally warmer places don’t have to compromise on performance.

- Sustainable solution – By reducing the need of using fans, chillers, compressors, etc. to cool your mining farm of datacenter, you also significantly reduce power drain. Our system does not require tap water for cooling, so water won’t be wasted just to process your data.

- Summary – Comparing an air-cooled system with a liquid-cooled one, it becomes clear that liquid is much more efficient and quiet solution to keep your installation protected from overheating despite overclocking or other sources of computing stress. It brings massive savings in labor costs and space requirement for installation and service.

Is your system a water cooling system?

Not exactly. You should think about it as liquid cooling or cooling with a dielectric fluid. Unlike gaming PC or overclocked CPUs that can be cooled with water, we use a specially designed fluid that removes heat from immersed devices (or submerged, per say). The fluid is non conductive – it’s dielectric. So there is no risk of damaging your electronics with water that will kill the components as it might happen with DIY water cooling of PC.

Our dielectric liquid has great heat capacity and it’s materially compatible with electronics – so it will not damage expensive ASIC miners.

Is that single-phase or dual-phase cooling?

Single phase means that during the cooling process the fluid doesn’t change its physical state. It remains liquid all the time. It means, it neither boils, nor evaporates. Such systems are very affordable and do not require lots of maintenance efforts during their operations. Fluid can remain in it for years if kept clean and away from water.

What is a dual-phase cooling? In this kind of process fluid is heated until it starts to boil and changes its state from liquid to vapor. In order to achieve it, fluid must absorb a large amount of energy. This process is very efficient for its cooling capabilities (better than single-phase and about 4000x better than free air cooling), but it also requires a much more complicated system (with chillers, vapor condensers) and must be sealed very precisely. Dual-phase fluids are at least 10x more expensive than typical fluids used in a single-phase system. On top of that, it requires lots of maintenance and constant leak checks.

Which one is better: single-phase or dual-phase cooling methods?

You want single-phase immersion cooling. Really. Single-phase means you are using special synthetic oil made for electronic components cooling. The cost of engineered fluid is approx € 216 or $ 241 per 25 liters or 6.6 gallons. This makes that economic solution as the fluid does not evaporate, the fluid lifecycle is almost endless, and additionally, it can be filtered/reconditioned multiple times.

Dual-phase system requires special synthetic/fluorochemical coolant available at many suppliers but usually known under the brand name of 3M – Novec”. The fluid evaporates (boils) at the temperature of 61C. It evaporates quickly, so it requires special hermetic sealed enclosures. Usually, people who try to use that fluid loose lots of money as 1kg (0.8 liters) costs approx $ 60 – it’s 6 times more than synthetic engineered fluid. So this is why you want a single-phase system.

Simply saying, if you are looking for cryptocurrency systems cooling option – a single phase system is for you. If you’re a millionaire and you’re running a large datacenter, you can afford dual-phase cooling. Remember that fluids used in dual-phase cooling are not only extremely expensive but also harmful for your health (when you inhale its vapor), as well as for the environment, having one of the highest GWP parameter (Global Warming Potential) among all other toxic substances.

What kind of hardware can be cooled with your system?

With DCX immersion system you can cool literally any kind of electronic hardware like IT equipment – servers, switches, storage (SSD or helium HDDs), GPU or ASIC miners, or any other kind of electronics you need to cool.

What does it mean “single-loop system”?

A single loop means that the fluid cools down your miners and then goes to a dry cooler, where it’s chilled, and goes back to the enclosure as colder fluid afterwards. It’s simple as it doesn’t require additional pumps or heat exchangers, but you must consider that precious coolant must fill the whole setup including tubes, pipes, and the dry cooler itself. For our smallest system, ~30 l of fluid is required just for that, but it’s a good ratio: money to simplicity and value.

What does it mean “dual-loop system”?

Dual loop systems are a bit more complicated than a single loop, but much better for bigger installations, especially those with large dry coolers or those with distant placement of enclosures and a cooler. A primary loop is filled with a water-glycol mixture which is cheap and very popular. The dry cooler and all pipes are filled with it. Sometimes it might be hundreds of liters.

A secondary loop is created on the enclosure level. A small pump circulates the fluid through a brazed plate heat exchanger. The coolant is chilled with the water out of the primary loop right there. These two fluids don’t mix with each other.

Dual loop systems are the best for heat utilization, as you can connect them easily to your facility heating system (that might be your home, office, swimming pool, greenhouse…). By reusing the heat you can make your mining operations more profitable and shorten the ROI time.

What's the lead time time of your products?

There’s one simple rule we stick to: first paid – first served. It makes a major impact on the lead time: once an order is paid and the payment is received by us, we start to assemble and pack the goods for shipment. Needless to mention, each and every single one of them wants their orders to be delivered ASAP. Another important factor that affects the lead time is the incredible customizability of products we offer. Each package is customized for every single client in terms of the space, location, configuration, temperature and many other variables. To sum it up, normally the preparation time can take 4-5 weeks. Later on comes shipment, the duration of which fully depends on choice of delivery method. You might be willing to ship the goods by plane (much faster but also much more expensive) or by sea (slower but for sure cheaper). So let’s assume that from the moment the payment is received by us to the moment you will receive the goods at your doors it can reasonably and realistically pass 6-8 weeks in total.

UPDATE: please note that the war touched us too – the supply chain for dry cooler components is almost broken. This is the reason for such a long lead time these days. However, we’ve got everything else in stock: immersion tanks, switchgear, fluid, sensors etc. If you come up with a heat reuse scenario that doesn’t require a dry cooler (e.g. connecting the immersion system to a swimming pool or house heating etc.), we can prepare your order much quicker! GPUs are more suitable for such scenarios, because they produce a minuscule amount of heat compared to ASICs. With ASIC miners, suhc scenarios are rather limited.

Please dig for inspiration here: https://cryptocooling.eu/installation-examples/ OR buy a dry cooler locally (it’s not a rare item). It will be more expensive, but the greedy pays twice.

Can I pay 20/30/40/50% now and the rest after receiving the order?

According to our terms and conditions, payments are 100% upfront. It only refers to smaller orders though (up to 1MW). When it comes to bigger scale-out solutions, we offer different flexible payment terms.

What assurance do I have with prepayment?

We are a recognised manufacturer that has been available on the market for 3 years already. We have already shipped over 1000 enclosures to literally every continent on the globe, and we’ve got tons of satisfied customers. Our short history is easily trackable. Please visit our social media to make sure you deal with a trustworthy manufacturer. Also, credit card payments are secured by online stripe services.

Can you send me a commercial invoice before I continue with a purchase?

We can send a proforma invoice to help you proceed with payment. Please note that proforma is just an invitation to payment and by no means is a legal document. A commercial invoice comes after the payment is received and registered on our bank account and can be treated as a legal confirmation of a successful transaction.

Can I get a discount?

We have a flat price scheme for all customers, so it means no discounts. Everybody gets the same price. Costs of our products are dictated by the prices for components and certain materials they are made of, such as copper and steel. Taking into account global trends, prices are going to grow up, unfortunately. If you consider buying a system, consider doing it now, before the costs skyrocket. Remember, the greedy pays twice.

Can you prepare an invoice with fake numbers, so that I pay less taxes?

As a matter of fact, we are a VAT registered company. It obliges us to follow certain local and international laws that we can’t neglect b y any means. Your desire to avoid paying taxes and customs fees is totally understandable, but we cannot provide a different value than the actual cost of your purchase, unfortunately.

Will I be able to get my money back if I suddenly change my mind?

Yes, of course. According to our general terms and conditions statement, we can keep 20% of the payment as a reimbursement for production costs and time our employees dedicated to you. However, we tend to refund 100% when there are other clients in the line, who would be eager to get a similar order a bit faster.

Do you accept crypto?

No, unfortunately. We’re located in Poland and we’re obliged to pay our taxes here. Poland has no legal regulation for cryptocurrency, so crypto is not an option here. We only accept usual wire transactions and credit card payments (the last comes with a 3% stripe fee though).

How can I proceed with the payment?

Please note that you’ve got all the necessary information at the bottom of the quote already. If your quote is in USD, it means that you should pay in USD and not in GBP, EUR and definitely not in PLN! Please don’t try to send us any other currency other than the one indicated in your quote if you don’t want your payment to be auto-converted not in your favor.

Can I pay with a credit card?

Sure you can. We use Stripe (https://stripe.com/) as a payment operator. A credit card payment comes with a 3% stripe fee though. Please ask your sales representative to add a button for credit card payment, so that you’ll be able to pay with only one click.

Can I split the payment if my bank account has a daily limit?

We can surely do this. Our sales representatives will be happy to help you out with it. But remember, your order will only start being processed when the full amount is paid.

Can I pay via PayPal?

Unfortunately, we don’t accept PayPal payments, only usual wire transfers and credit card payments (the last comes with a 3% stripe fee though). If you want to pay with a CCD, please ask the sales representative that you’re in contact with to add a button for it.

What are the Terms and Conditions of sales?

There are two certain places where you can find them. The first one is the quote you get from a sales manager. The second one is our website. Please follow this link to see DCX General Terms and Conditions: https://cryptocooling.eu/terms-and-conditions/

Do you sell miners/GPUs?

No, we sell neither ASIC miners, nor GPUs. We’re no financial advisors either. In fact, we’re a small Polish company producing immersion cooling equipment only.

Do you sell crypto?

No, we don’t sell cryptocurrency. We’re no financial advisors either. In fact, we’re a small Polish company producing immersion cooling equipment only.

Do you sell firmware?

No, we don’t sell firmware. In fact, we’re a small Polish company producing immersion cooling equipment only. However, if you’re looking for firmware that would allow your devices for overclocking, we recommend making a research on these companies: Vnish, Braiins, HiveOS.

Do you ship to the USA/Canada/Australia etc.?

Yes, we basically ship everywhere, as far as DHL can reach. Don’t mistake DHL Express with DHL Global Forwarding though – they are basically two separate companies and Global Forwarding is the one we work with.

Is shipment cost already in the quote?

Shipment costs are never included in quotes, unless you’re located somewhere relatively not far from us. Since we’re based in Europe, we already add shipment cost to countries within the EU. If you’re far away from us though, we usually use DHL Global Forwarding as a forwarder. In that case, we need to apply for a proper shipment cost estimation – by sea or by air.

Can I get a shipment quote?

Of course we can provide you with a shipment quote. If you decide to proceed with air delivery (the most expensive one) or dedicated sea shipment (medium cost), I can apply to DHL Global Forwarding for cost evaluation. Please note that sometimes we have to wait for several days (or even a week) for their response. Also, DHL GF refuses to deliver anything to individual customers, they only deal with companies (it’s an obligatory condition).

How long does delivery take?

Air freight takes only 1 week, but costs more. Ocean freight takes 4 weeks and costs a bit less. Delivery within the EU takes not longer than a week.

When do I need to pay for the shipment?

It’s your choice. We can add a shipment cost to the initial quote, or you can pay for it after your order is ready and packed. Please note that shipment cost estimations are only valid through 2 weeks, so by the time the package is ready, it will already be expired. In that case we refresh the old shipment cost estimation and you cover the difference (if it occurs). In fact, the difference is always insignificant (within $100-$200) for smaller purchases, such as single enclosure systems. Obviously, for bigger orders such difference in costs grows exponentially.

Can I arrange a shipment myself?

Certainly you can. Moreover, our employees would be grateful to you for saving their time and effort. We will provide package weights and dimensions, as well as HTS codes and, most importantly, pickup address.

Can you arrange a shipment for an individual customer?

Yes, we can certainly do this. However, we would recommend to order as a company, since DHL Global Forwarding refuses to deal with individual clients. Dealing with another forwarder usually means higher costs and sometimes lower service quality, such as inability to track a shipment, for instance.

Who pays for local taxes, fees, customs procedures?

There are several options to choose from when it comes to shipment. Some clients find it more comfortable to use Incoterms EXW conditions. It allows them to pick up the order directly from our shipping warehouse. In addition to that, we can quote door-to-door shipping services individually. You can also arrange pickup of the package on your side from a local terminal. If we quote shipping services (usually via DHL Global Forwarding or other recognised forwarder) DCX delivers according to DAP procedure: the products are delivered to a formerly designated place of destination, but DCX is not responsible for unloading packages. DCX’s responsibilities include packing, export clearance and carriage expenses up to an agreed destination. A customer has to cover all costs such as customs duties, import clearance, taxes and unloading. In case of DAP delivery, clause 3 hereinbelow applies accordingly. Please see more here: https://cryptocooling.eu/terms-and-conditions/

What are HS codes of your equipment?

1 DCX Immersion Mining Enclosure 8419.89.95.40

2 ThermaSafe R Dielectric Engineered Fluid 22L NEW: 3902.90.9099

3 40kW ICP40 DryCooler / 120kW DryCooler 8419.89.95.40

4 Manual pressure test pump 8413.81.00.40

5 40 kW Switchgear box or PDU 8536.20.0040

6 DC Temperature Sensor 8517.69.00.00

7 Fan emulator – 4 pin / 6 pin 8542.31.00.01

8 Dielectric Solvent 10L 3402.49.9000

Do we need special certification or approvals for the mechanical systems or fluids?

Thermasafe R dielectric engineered fluid is:

1) Considered non-toxic with acute toxicity 1.

2) In terms of oral, dermal, inhalation, skin corrosion / irritation / serious damage eye irritation, respiratory or skin sensitization), it is not classified as acute toxicity based on available data / based on available data, the toxicity classification criteria are not met.

3) It is distributed as part of the other product, so not requiring regulation by TSCA

4) Exempt from the TSCA certification by the federal regulations

—> https://www.govinfo.gov/content/pkg/CFR-2019-title40-vol33/xml/CFR-2019-title40-vol33-part711.xml

§ 711.6 Chemical substances for which information is not required.

The following groups or categories of chemical substances are exempted from some or all of the reporting requirements of this part, with the following exception: A chemical substance described in paragraph (a)(1), (a)(2), or (a)(4), or (b) of this section is not exempted from any of the reporting requirements of this part if that chemical substance is the subject of a rule proposed or promulgated under TSCA section 4, 5(a)(2), 5(b)(4), or 6, or is the subject of an enforceable consent agreement (ECA) developed under the procedures of 40 CFR part 790, or is the subject of an order issued under TSCA section 5(e) or 5(f), or is the subject of relief that has been granted under a civil action under TSCA section 5 or 7.

(1) Petroleum process streams. EPA has designated the chemical substances listed in Table 1 of this paragraph by CASRN, as partially exempt from reporting under the CDR.

Most of the hydrocarbonated fluids are exempt as per Table 1—CASRNs of Partially Exempt Chemical Substances Termed “Petroleum Process Streams” for Purposes of TSCA Chemical Data Reporting

We do not process / we are not required to present any specific certification besides complying with standard requirement of importing chemical goods:

– Not importing for any prohibited use

– Satisfying all applicable labeling and MSDS requirements

– Not exceed any specified restrictions on permissible import volume

– Not be imported for any designated significant new use

– Complying with any other applicable requirements

How to start:

What do I need for immersion cooling?

You need an enclosure, a tank or a bath filled with dielectric fluid, that will house your miners. The tank needs hydraulic fittings with correct diameter that will provide inlet and outlet of the fluid. The fluid must circulate, so we need the pump that will provide enough liters per minute flow. The fluid goes through the miners, takes the heat and warms up. This hot fluid must be redirected out of the enclosure – so we need some heat exchanging or rejection device. It can be just a brazed plate heat exchanger that has a “hot” and “cold” side. A dry cooler or, for example, tam water (but that would waste so much water) should be connected to the plate heat exchanger. If you want to use the dry cooler option, make sure to connect it to the enclosure with tubing that we also provide. Since the dry cooler requires fresh air it must be placed somewhere outside the building, ideally in sunshade, on the north side of the building. That’s it: an enclosure with fluid and miners, pumps that circulate the fluid, tubing, and heat exchanging device as a dry cooler.

Miners must be prepared with custom firmware and sometimes undergo small changes (removal of thermal paste from ASIC chips or PSUs), so the lack of fans will not be a problem for the system.

What do you provide?

We design, manufacture, and deliver all components of the immersion cooling system: enclosures, dielectric cooling liquid, heat exchangers, dry coolers, all complimentary components like switchgear, monitoring sensors and software, fittings, tubing, accessories, pumping stations, etc. We serve customers that require a simple single enclosure, rack systems, or even containers for scale-out installations.

What kind of preparation is needed for the hardware to be immersed?

Just a few simple steps:

New miners require

- removal of the fans

- opening the PSU covers, removal of thermal paste from a few components

- installation of custom firmware that will not require fans to operate any more

- removal of stickers with a heat gun if possible

- compressed air cleaning

- immersion in the fluid and shake cleaning if possible.

Used miners require:

- removal of the fans

- installation of custom firmware that will not require fans to operate any more

- opening the PSU covers, removal of thermal paste from a few components

- removal of stickers with a heat gun if possible

- detailed cleaning with compressed air

- ideal two-stage: spray cleaning before immersion/shake cleaning in the cleaning bath

A general rule is to:

- Remove all unnecessary parts like fans, plastic covers, sidewalls, etc. And anything that can block fluid flow;

- Remove fans, which requires custom firmware to eliminate any alarms or shutdowns that occur when the fans are not discovered by the system or rotation speed is below some threshold that generates system alerts. There is a lot of free firmware available, some manufacturers like MicroBT provide custom firmware for Whatsminers for free;

- If it’s not possible to shut off the fans on the power supplies, it’s not a problem, so it’s ok to allow the PSU fans to run in the fluid;

- Most miners have solid thermal epoxy. If not thermal paste or pads (for example from GPU or CPU or PSU components) must be removed and replaced with solid material (we will advise);

- Install software or hardware that will allow you miner to work without the fan (cheat the system). It’s so-called “spoofer” and the same effect can also be achieved with special software – also good for overclocking;

- Clean the unit firmly (compressed air is good, but maybe not sufficient). You can use special cleaning fluids or solvents.

After immersion – no dust, no corrosion, no burned boards as the dielectric fluid protects from overheating, vibration, shortcuts, dust etc.

Facility / Heat rejection devices

How to remove heat from my immersion system?

How to remove heat?

As described on installation examples and our quick video startup manual the cooling system requires a heat rejection device. The immersion system is used to transfer heat from the miners in a silent and very effective manner. But it also requires some device or loop where that 20-30-40-80-120kW heat will be redirected. Since we use hot mining method (the temperatures in our enclosures may reach 60C/140F and above), we have a very effective heat transfer, even in hot or humid climate. Whether its single enclosure, a rack or multiple racks – we have 3 options to connect to our system and remove heat:

1. water connection to home/facility heating or a cooling loop

2. water connection to tap water

3. or connection to a dry cooler.

In this setup, our Liquid 2 Liquid (L2L) Immersion Enclosure has its own pump and heat exchanger which circulates our dielectric heat transfer fluid inside the system. Thermasafe R dielectric liquid is very effective at heat pickup. Fluid circulates internally and takes the heat from immersed miners. Then the heat is transferred with the enclosure brazed plate heat exchanger to external water or water-glycol loop. As mentioned it can be tap water/home heating loop/direct connection to the pool or nearby lake – everything is possible! But what is most convenient is the connection to an external dry-cooler.

Description of the available options:

ad 1. At home, you can use a connection from our dual loop enclosures to the heating loop. In moderate or cold regions most of the houses have their own separate heating/cooling loop. This local system can reuse heat from the miners if needed, and there will be multiple contractors available to connect it to your loop without any problem. The heat from the miners can heat up home radiators, pools, water boilers, or even jacuzzi. And that can be connected by local heating services/installation companies.

ad 2. If you live in a flat you use tap water. The problem may be the bill for water but you’ll have a silent operational system of 20-60 miners at your home. Water connection requires 0.5 to 1 m3 of water per hour. Our L2L enclosures can be connected to tap water without any additional investment.

ad 3. Dry coolers are the most effective way to remove heat. They can be installed either vertically or horizontally. They do generate some noise but it’s just 51-55 dB(A) 10m away. Dry coolers must be placed outside – near the building or on a flat rooftop. It is ok for commercial or industrial area, but rather not for residential / housing areas. The dry cooler is a close loop system so no water is wasted – it circulates the same water/glycol mixture.

We have a broad portfolio of dry coolers – see them here. And there are 3 basic types quickly available:

– a) 32kW (35C outside) / 42kW (20C outside) dry cooler. A small system for a single enclosure has its own pumping system that will circulate the fluid for a 10-20 meters of tubing.

– b) 80kW dry cooler for 2 or 3 enclosures with limited capacity – require pumping station which we also deliver.

– c) 127kW dry cooler – a larger 2 x 2 m dry cooler that supports a single rack with maximum capacity – requires pumping station, which we also deliver.

Cryptomining Immersion Enclosure or Cryptomining Immersion Rack has multiple options to remove the heat. With a small help of the chiller unit, they can use an additional source of cold water, even in very hot regions or countries. The L2L enclosures can be also installed as a part of a bigger system and used for heat reuse. A 99% of the heat from the miners can be reused for any commercial application (farming / drying ) or home/company heating.

dielectricfluids.eu

dielectricfluids.eu cryptocooling.eu

cryptocooling.eu