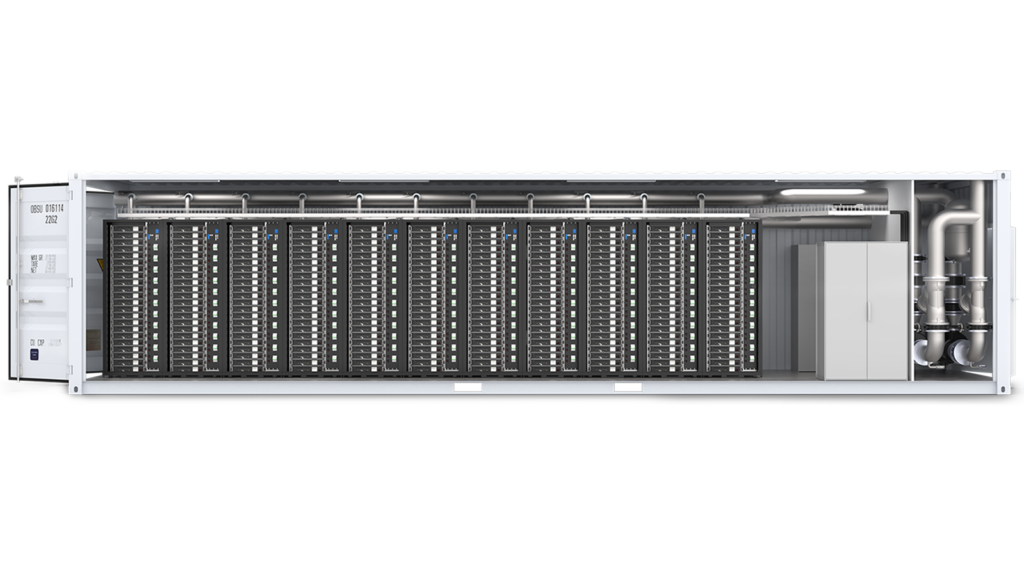

Small but dense Immersion Crypto Mining Containers as DCX patent pending containerized system with immersion liquid cooling technology is the answer for all the problems that bother industry sized cryptocurrency mining farms. DCX Immersion Mining Containers solves all issues with proprietary, patent-pending granular Immersion Enclosure fluid distribution. The unmatched density of 700 to even 800 ASIC miners installed in immersion enclosures results in 2 to 4 MW power density. Each of our Immersion Containers is equipped with its own second loop pumping and heat exchange station. DCX’s second loop fluid distribution system circulates our ThermaSafe R dielectric Heat Transfer Fluid. Single-phase liquid has 1600 x better heat capacity and 4.5x better heat conductivity than air. Our fluid transports 100% of heat outside the enclosure and protects devices from the harsh environment and failure mechanisms including high temperature, humidity, vibration, corrosion, dust – major causes of electronic failures. Reduces thermal expansion cycling, maintains a constant temperature, eliminates airborne contaminants, and failures due to zinc and tin whisker growth. ThermaSafe R works also as a fire suppressant making sure you are protected even in remote mining operations.

Based on the DCX Scale Out PRO10 Immersion Enclosures and Immersion Rack Systems, PRO10 HD container includes a complete hydraulic system. Containers are available with maximized miners density (all rack build) or with Low Power Switchgear components to be built-in within the container frame. Available in standard 20HC or 40HC ISO format, easy to transport and commissioning at any destination, PRO10 HD containers are based on standard ISO container and hold CSC certification. System can be delivered with:

- complete immersion cooling system with hydraulic loop and standard adaptations & wiring built-in, to be later integrated with switchgear option at investor site,

- turnkey solution including switchgear, power distribution and all options and accessories for region specific (UL / CE / ELTEK) certification.

System capacity:

- – 20HC: 2MW Heat Transfer Capacity 256 x S19 / 320 x M56 / 384 x M30

- – 40HC: 4MW Heat Transfer Capacity 576 x S19 / 720 x M56 / 864 x M30

System density options:

- DCX 20HC: 2MW Heat Transfer Performance – 256 x S19 / 320 x M56 / 384 x M30

- DCX 20HC-PD: 1.7 MW Heat Transfer Performance. Turnkey system with full power distribution (switchgear) and accessories included – 192 x S19 / 240 x M56 / 288 x M30

- DCX 40HC: 4MW Heat Transfer Performance – 576 x S19 / 720 x M56 / 864 x M30

- DCX 40HC-PD: 4MW Heat Transfer Performance. Turnkey system with full power distribution (switchgear) and accessories included – 512 x S19 / 640 x M56 / 768 x M30

dielectricfluids.eu

dielectricfluids.eu cryptocooling.eu

cryptocooling.eu