A complete Antminer Hydro Cooling System. Our standard ICP15 adaptive dry cooler with controller firmware update to control dew point combined with S19 compatible flowplates, a manifold and cooling fluids. A working solution to upgrade current Antminers into the hydro model or utilize affordable hydro miner series at small, home-scale. This kit will support up to 15kW of heat transfer from your miners.

ICP15 Adaptive Cooling / Pumping System Hydro kit

A complete Antminer Hydro Cooling System. Our standard ICP15 adaptive dry cooler with controller firmware update to control dew point combined with S19 compatible flowplates, a manifold and cooling fluids. A working solution to upgrade current Antminers into the hydro model or utilize affordable hydro miner series at small, home-scale. This kit will support up to 15kW of heat transfer from your miners.

ICP 15 is an Industrial dry cooler combined with integrated pump and adaptive fan control. Provides 15.87 kW of Heat Transfer at 35°C and 21 kW of Heat Transfer at 25°C. A complete solution, replacing dry cooler and a separate pump group. Over 3 times more effective than simple machine oil coolers. Equipped with adaptive fan controller which controls the speed of the fans, so they operate as silent as possible. ICP 15 may be combined with heat reuse loop and is ideally sized for home mining operations.

We supply our customers with:

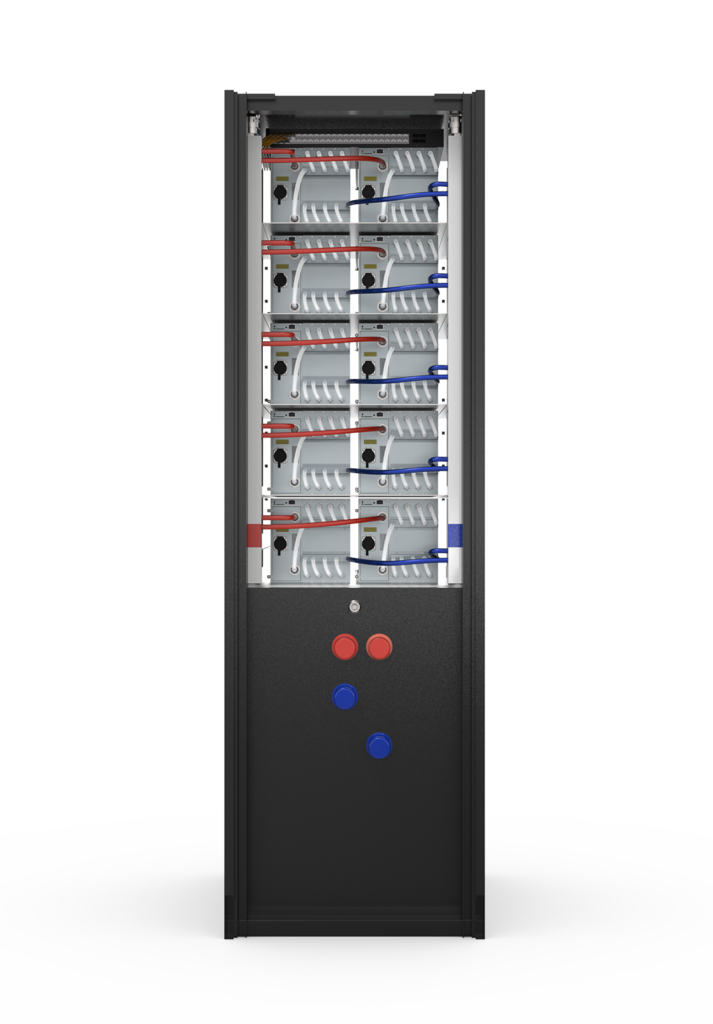

DCX HYDRO100 Rack CDU Technical Specifications

| DCX 100 HYDRO RACK | Whatsminer | Whatsminer | Bitmain | ||

|---|---|---|---|---|---|

| Miner Capacity | 10 single pump with full redundancy | 12 dual pump | 10 single pump, 20-30 dual pump | ||

| Heat Transfer Capacity (kW) | 75 | 115 | 112-163 | ||

| Max Power / Miner (kW) | 7,4 | 9.4 | 5.45 | ||

| CDU Operating Power (W) | Single pump 1500W | Dual Pump 3000W | Single 1500W or Dual Pump 3000W | ||

| Primary Loop Temperatures | Supply 20-50°C | Return 40-70°C | ||||

| Ambient Operation Temperature | -30°C~50°C | -22°F~122°F | ||||

| Ambient Humidity | 5-95% RH | ||||

| Input voltage | 3P custom / standard 380-440V 50/60HZ | 1P 220V or 230V 50/60H | ||||

| Dimensions (LxWxH) | 600x800x1950 | ||||

| Weight (KG) | 220 kg | ||||

| Pipe connection diameters | DN32 / DN40 | ||||

| BPHX / Heat Reuse Capacity | 40-100 kW | ||||

| Certification | CE | UL & ETL at request | ||||

| Primary Loop Monitoring & Control | Remote monitoring & control: Flow, Temperatures | ||||

| Rack Monitoring | Remote monitoring: Individual Temperature Monitoring | ||||

| PDU (if included) | Remote monitoring & control: Power, Voltage, Alarms, Reset | ||||

| Heat Reuse | Facility connection providing return temp 20-50°C | ||||

| Heat Rejection to Dry Cooler | DCX 40-120kW Immersion Optimized Dry cooler | ||||

DCX HCS15 Technical Specifications

DCX HCS40 Technical Specifications

Quick intro

Unboxing of the Immersion Enclosure package and quick intro to the system components.

What you get – bundle

Enclosure with a 40kW dry cooler. We have a new ICP40 now, but you see what you get in the bundle package.

Installation & Startup

You bought the package – now what? Quick installation guide for effective commissioning of this smart immersion cooling system.

Get in Touch

We’d love to help you in your project with our liquid cooling systems.

Get your custom quote sized to your needs:

We need basic information required to size the DCX Immersion Mining system correctly:

- type and number of ASIC miners or GPUs

- expected miners power

- your plan for heat rejection – we can deliver immersion optimized

- dry cooler or connection to local water loop

- city / country of your operation – to make sure w will deliver

- expected performance in your maximum ambient temperature and to quote shipping cost.

Get in Touch

We’d love to help you in your project with our liquid cooling systems.

dielectricfluids.eu

dielectricfluids.eu cryptocooling.eu

cryptocooling.eu